Our company is a leading enterprise in China that has long been committed to the R & D, production, manufacturing and sales of the semiconductor's leading frame mold and (integrated circuit IC) the post-process packaging equipment .

As a professional semiconductor semiconductor package equipment is used in precision processing made by semiconductor equipment corporation,it need semiconductor tooling,spares part,and as well as plastic molding kit. We have advanced production equipment and technical teams that can service according to customer needs.

In terms of foreign trade development, we have rich experience and wide customer network. In the 13 years since the establishment of the company, our products have been successfully exported to more than 50 countries and regions such as Russia, France, Germany, Japan, the United States, Brazil, India, Thailand, Hong Kong, Malaysia, and Saudi Arabia and have received the unanimous praise from global customers.

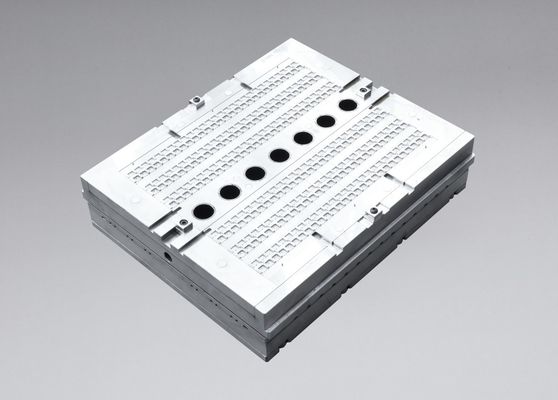

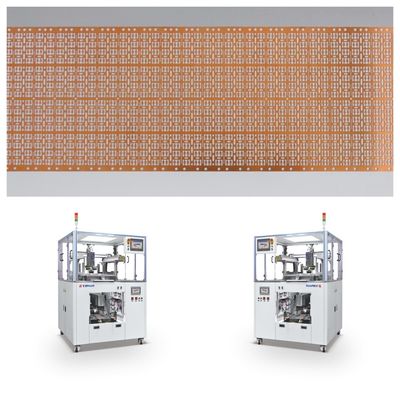

We make a series of molds required to include the Auto Molding system , Trim & Form singulation System ,Lead frame stamp tools,MGP mold and other semiconductor's post—processes. Whether it is semiconductor separate devices, capacitors, inductors, resistors, bridge circuits, vehicle electrons, etc., or the LED industry, the LED industry's MicroLED & mini-led solid packaging. We not only provide a plan for your newly developed products, but also provide suggestions from the aspects of improving product quality and improving costs for the products that exist in production.

If you are interested it, we can talk in detail and look forward to cooperating with you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!