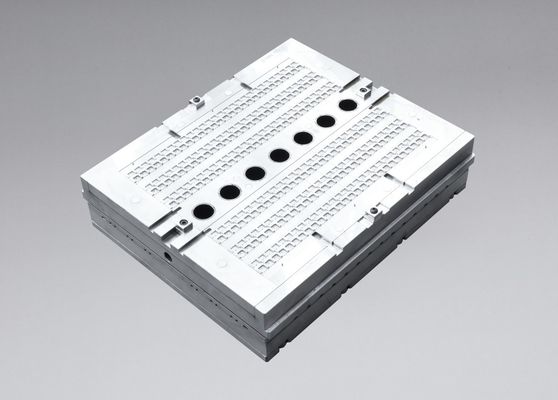

DIP4/8/14/16/18/23/24/25/29/40 MGP Mold

Features:

- Product Name: IC Lead Frame Stamping Mold

- Mold Material: NAK80, S136, SKD61, Etc.

- Surface Treatment: Nickel Plating

- Runner System: Hot Runner/Cold Runner

- Mold Design: 3D/2D

- Material: Steel

- Semicon IC Lead Frame Mold

- High-Precision IC Lead Frame Mold

- High-Life IC Lead Frame Mold

Technical Parameters:

| IC Lead Frame Stamping Mold Technical Parameters |

| Mold Life |

100,000 Shots |

| Mold Cooling System |

Water Cooling |

| Application |

IC Lead Frame Stamping |

| Surface Treatment |

Nickel Plating |

| Lead Time |

4-6 Weeks |

| Runner System |

Hot Runner/Cold Runner |

| Mold Material |

NAK80, S136, SKD61, Etc. |

| Cavity Number |

Single |

| Mold Type |

Stamping Mold |

| Mold Base |

LKM, DME, HASCO, Etc. |

| IC Lead Frame Stamping Mold Features |

| Hige-Quality Lead Frame Mold |

This mold is made with high-quality materials and precision manufacturing techniques to ensure the best performance and longevity. |

| Semicon IC Lead Frame Mold |

Specifically designed for the production of semiconductor IC lead frames, this mold provides high precision and efficiency. |

| Lead Frame Mold |

This mold is designed to create lead frames for electronic components, making it an essential tool in the electronics industry. |

| IC Lead Frame Stamping Mold |

The stamping process allows for high-speed and high-volume production of IC lead frames, making this mold ideal for mass production. |

Applications:

Brand Name: TJIN

Model Number: 006

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1

Packaging Details: Wooden Packaging

Delivery Time: 40 days

Payment Terms: TT

Mold Design: 3D/2D

Mold Size: Customized

Cavity Number: Single

Surface Treatment: Nickel Plating

Mold Cooling System: Water Cooling

Application

The IC Lead Frame Stamping Mold, manufactured by TJIN, is a high-quality and precision mold designed for the production of lead frames for integrated circuits. It is widely used in the electronics industry, particularly in the manufacturing of semiconductors.

The lead frame is an essential component in the production of integrated circuits as it provides a platform for the electronic components to be mounted and connected. The IC Lead Frame Stamping Mold plays a crucial role in creating the lead frame with high precision and accuracy, ensuring the proper functioning of the integrated circuit.

With its 3D/2D mold design, the IC Lead Frame Stamping Mold allows for the customization of the lead frame size and shape, catering to the specific needs of different integrated circuits. The mold design also ensures the production of a single cavity, providing a consistent and uniform lead frame for efficient and reliable integrated circuit production.

Product Features

- High-quality and precision mold for lead frame production

- Customizable mold size and shape

- 3D/2D mold design for accurate and consistent production

- Single cavity for uniform lead frame production

- Nickel plating for enhanced durability and corrosion resistance

- Water cooling system for efficient cooling and faster production

- Certified with ISO9001 for quality assurance

- Suitable for the production of various integrated circuits

- Wooden packaging for safe transportation and storage

Customization:

TJIN - IC Lead Frame Stamping Mold Customization Service

Brand Name: TJIN

Model Number: 006

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1

Packaging Details: Wooden Packaging

Delivery Time: 40 days

Payment Terms: TT

Application: IC Lead Frame Stamping

Runner System: Hot Runner/Cold Runner

Cavity Number: Single

Tolerance: ±0.01mm

Mold Cooling System: Water Cooling

Hige-Quality Lead Frame Mold

Semicon IC Lead Frame Mold

Packing and Shipping:

IC Lead Frame Stamping Mold Packaging and Shipping

Thank you for choosing our IC Lead Frame Stamping Mold! We are committed to providing you with high-quality products and excellent service.

Packaging

Our IC Lead Frame Stamping Mold will be carefully packaged to ensure its safe delivery to you. The packaging will include:

- Sturdy cardboard box or crate

- Bubble wrap or foam padding

- Protective plastic wrapping

- Product manual or instructions

These materials will protect the mold from any damage during transit.

Shipping

We offer several shipping options to meet your needs:

- Standard shipping: Estimated delivery within 5-7 business days

- Expedited shipping: Estimated delivery within 2-3 business days

- International shipping: Estimated delivery time varies by location

Once your order is processed, you will receive a tracking number via email to track your shipment.

Please note that shipping costs may vary depending on the shipping method and your location.

Customs and Duties

For international orders, please be aware that customs and duties may apply. These fees are the responsibility of the customer and are not included in the product price or shipping cost.

If you have any questions or concerns about the packaging or shipping of our IC Lead Frame Stamping Mold, please don't hesitate to contact us. Thank you again for choosing our product.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 006.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: Does this product have any certification?

A: Yes, this product is certified with ISO9001.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1.

- Q: How is this product packaged for delivery?

A: This product is packaged in wooden packaging.

- Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 40 days.

- Q: What are the available payment terms for this product?

A: The available payment terms for this product are TT (Telegraphic Transfer).

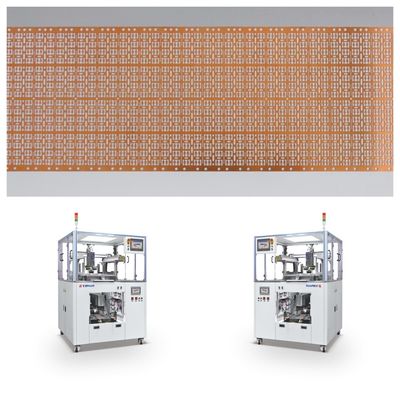

Main packaging form

To series: T0220/263/247/252/3p, etc.;

SOP series: SOP4/6/8/8/1 0/12/14/16/20/28;;

DIP series: DIP4/8/14/16/18/23/24/25/29/40;

SOT series: SOT23/25/26/223/89;;

SOD series: S0D123/323/523/723/923;

QFN/BGAPDFNOFP/SMA/MBF/TSSOP series, etc.;

Technical Parameters

1. Plastic dual -oil cylinder with a built -in gear shift drive multi -injection molding design;

2. Cavity Bar uses high-speed powder steel, hardness HRC62-64;

3. Surface vacuum coating, the life span is not less than 300,000 times;

4. The roughness of the cavity can achieve 0.2um.max;

5. Special products can increase the design of vacuum and built -in core pumping mechanisms;

6. According to the size of different lead frames, 8 tablets/12 pieces/16 tablets per mold can be achieved.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!