Semiconductor Packaging Equipment

Features

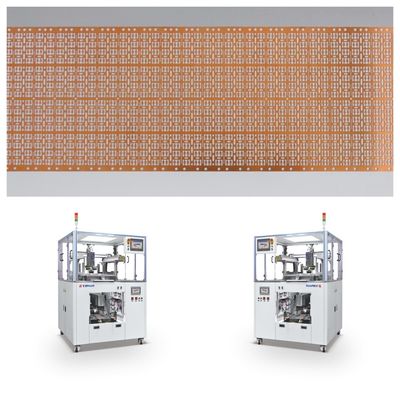

● Automatic molding press also known as automatic molding machine, automatic molding chips, semiconductor devices and other products;

● Full servo control system, PLC (Omron) + controller;

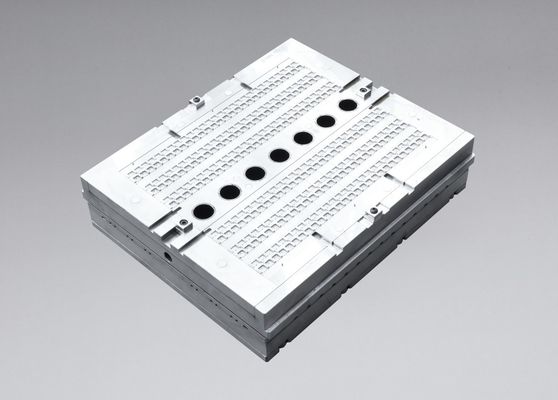

● Standardized mold structure, easy to change;

● High efficiency cake loading component, aluminum box loading;

● Automatic cassette loading, double cassette stacked loading;

● Supports flexible expansion of up to 4 groups of presses to realize high UPH;

● Equipped with vision system to recognize the feeding direction;

● WIN10 + 15 inch touch screen + touch keyboard;

● CCD image detection, feeding anti-reverse detection;

● Optional mold vacuum function, isolation mold function, detection function after plastic sealing;

● Use of imported raw materials, high precision, stable performance, high service life, quality assurance;

● Customized on demand, permanently provide quality service.

Product Description:

Semiconductor Molding Equipment

Product Overview

The Semiconductor Molding Equipment is a fully automatic molding system designed for the production of high-quality semiconductor products. This advanced equipment utilizes state-of-the-art technology and features to ensure efficient and safe operation, making it an ideal choice for semiconductor manufacturers.

Safety Features

The Semiconductor Molding Equipment is equipped with advanced safety features to ensure safe operation and protect workers from potential hazards. These features include automatic shut-off systems, emergency stop buttons, and safety guards, providing a secure working environment for operators.

Molding Method

The molding method used in this equipment is injection molding, which is a highly efficient and precise technique for producing intricate semiconductor products. This method allows for the creation of complex shapes and designs with exceptional accuracy and consistency.

Control System

The control system of the Semiconductor Molding Equipment is powered by a PLC (Programmable Logic Controller), enabling accurate control of the entire molding process. This system ensures precise and repeatable results, reducing the risk of errors and increasing productivity.

Energy Consumption

This equipment is designed to be energy-saving, with low energy consumption compared to traditional molding machines. It utilizes advanced technology to optimize energy usage while maintaining high efficiency, resulting in cost savings for the manufacturer.

Automation

The Semiconductor Molding Equipment is a fully automated machine, eliminating the need for manual labor and increasing production efficiency. It is equipped with automatic molding presses, allowing for continuous production without the need for frequent manual interventions.

Benefits

- Highly efficient and precise molding process

- Accurate control and repeatable results

- Energy-saving and cost-effective

- Fully automated for increased productivity

- Advanced safety features for safe operation

- Optimal for producing high-quality semiconductor products

The Semiconductor Molding Equipment is the perfect solution for semiconductor manufacturers looking to improve their production processes. With its fully automatic molding system, advanced injection molding technology, accurate control, energy-saving features, and advanced safety measures, it is a reliable and efficient choice for any semiconductor production facility.

Performance Parameters

● Mold closing pressure: 98-1764kN;

● Injection pressure: 4.9-30kN adjustable;

● Applicable leadframe/substrate size: width 20-90mm, length 100-300mm, thickness 0.15-1.2mm;

● Applicable molding material size: diameter φ 11-20mm, length/diameter 1.2-2.0 (Max 35mm).

Technical Parameters:

| Technical Parameters |

Value |

| Application |

Semiconductor Industry |

| Molding Method |

Injection Molding |

| Temperature Control |

Precision Temperature Control |

| Automation |

Fully Automated |

| Product Type |

Molding Equipment |

| Capacity |

High |

| Energy Consumption |

Low |

| Safety Features |

Advanced |

| Material |

Plastic |

| Precision |

High |

| Additional Features |

Automatic Molding Press, Plasticizing Press, Fully Automatic Molding System |

Applications:

Semiconductor Molding Equipment - TJIN 002

Welcome to the world of high precision and advanced technology with TJIN 002 - the ultimate Automatic Molding Machine for the Semiconductor Industry. Trust us to provide you with the best solutions for all your molding needs.

Brand Name: TJIN

TJIN is a renowned name in the world of molding equipment, known for its high-quality products, advanced technology, and exceptional customer service. With our TJIN 002 model, we are taking a step further to revolutionize the Semiconductor Industry.

Model Number: 002

TJIN 002 is our latest model of Automatic Molding Machine, specially designed for the Semiconductor Industry. It is equipped with state-of-the-art features and advanced technology, making it the most efficient and reliable molding machine in the market.

Place of Origin: China

TJIN 002 is proudly designed and manufactured in China, the hub of technological innovations. With our team of highly skilled and experienced engineers, we ensure that each and every machine is built to perfection and meets the highest quality standards.

Safety Features: Advanced

At TJIN, your safety is our top priority. That's why our TJIN 002 model is equipped with advanced safety features to ensure a safe and secure working environment. From emergency stop buttons to overload protection, we have got you covered.

Precision: High

When it comes to molding, precision is crucial. With TJIN 002, you can expect the highest level of precision in every molding process. Our machine is designed to deliver accurate and consistent results, ensuring that every product meets your exact specifications.

Maintenance: Easy

We understand that time is money in the fast-paced Semiconductor Industry. That's why we have designed our TJIN 002 model to require minimal maintenance. With easy-to-follow instructions and simple maintenance procedures, you can save both time and money.

Energy Consumption: Low

With rising energy costs, it is essential to invest in equipment that is energy-efficient. TJIN 002 is designed to consume low energy while delivering high-quality results. This not only helps in reducing your energy bills but also contributes to a greener and more sustainable environment.

Capacity: High

TJIN 002 is a high-capacity Automatic Molding Press, designed to meet the demands of the fast-paced Semiconductor Industry. With its advanced technology and efficient design, it can handle large volumes of production without compromising on quality.

Application and Scenarios

TJIN 002 is the perfect solution for all your molding needs in the Semiconductor Industry. Whether you need to mold small, precise components or large, complex structures, our machine can handle it all with ease. Here are some of the common applications and scenarios where TJIN 002 can be used:

- Manufacturing of semiconductor chips

- Production of integrated circuits

- Manufacturing of transistors and diodes

- Production of microprocessors and memory devices

- Creating components for electronic devices such as smartphones, laptops, and tablets

- Molding of plastic and metal parts for electronic devices

With TJIN 002, you can achieve high precision, efficiency, and productivity, making it a valuable addition to your production line. So why wait? Contact us today to learn more about our product and how it can benefit your business.

Customization:

Welcome to TJIN Semiconductor Molding Equipment

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Customized Service for Molding Equipment

Product Description:

The TJIN Semiconductor Molding Equipment is a top-of-the-line product designed specifically for the semiconductor industry. It is a Fully Automated Molding Equipment that provides efficient and high-quality encapsulation for semiconductor products. With its Advanced Safety Features and Short Cycle Time, it is the perfect choice for any semiconductor manufacturing facility.

Key Features:

- Automatic Encapsulation System

- Automatic Molding Machine

- Fully Automated

- Advanced Safety Features

- Short Cycle Time

Application:

The TJIN Semiconductor Molding Equipment is specifically designed for use in the semiconductor industry. It can easily handle a wide range of products and is perfect for any encapsulation needs.

Advantages:

With its Fully Automated system, the TJIN Semiconductor Molding Equipment provides a seamless and efficient encapsulation process. The Advanced Safety Features ensure the safety of both the equipment and the operators. Additionally, the Short Cycle Time allows for a faster production process, increasing productivity and reducing costs.

Contact Us:

For more information about our TJIN Semiconductor Molding Equipment and our customized services, please contact us at sales@tjin.com or visit our website at www.tjin.com.

Packing and Shipping:

Packaging and Shipping for Semiconductor Molding Equipment

Our Semiconductor Molding Equipment is carefully packaged and shipped to ensure safe delivery and protection of the product.

Packaging

- The equipment is first wrapped in protective foam and then placed in a sturdy cardboard box.

- Additional padding is added to the box to prevent any movement during transportation.

- The box is sealed and labeled with appropriate handling instructions.

Shipping

We offer both domestic and international shipping for our Semiconductor Molding Equipment. Our standard shipping method is via air or sea freight, depending on the destination.

For domestic shipping, we partner with reliable carriers to ensure timely and secure delivery.

For international shipping, we work closely with our logistics partners to handle all customs and documentation requirements for smooth delivery to your location.

Once the equipment is shipped, we provide you with a tracking number so you can monitor the status of your delivery.

For urgent orders, we also offer expedited shipping options for an additional fee.

At Semiconductor Molding Equipment, we take great care in packaging and shipping our products to ensure they arrive at your doorstep in perfect condition.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 002.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: What is the main function of this product?

A: The main function of this product is to mold semiconductor materials.

- Q: Is this product suitable for mass production?

A: Yes, this product is designed for mass production of semiconductors.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!