Automatic Molding System

Product Description:

Semiconductor Molding Equipment

Our Semiconductor Molding Equipment is designed specifically for the semiconductor industry and offers a fully automatic molding system with advanced control capabilities.

With our state-of-the-art PLC control system, our equipment ensures precision and efficiency in the molding process.

The low energy consumption of our equipment makes it a cost-effective choice for companies looking to reduce their energy usage and costs.

Our product is a molding equipment, perfect for encapsulating semiconductor devices for protection and improved performance.

One of the key features of our equipment is its advanced safety features, ensuring a secure and reliable operation.

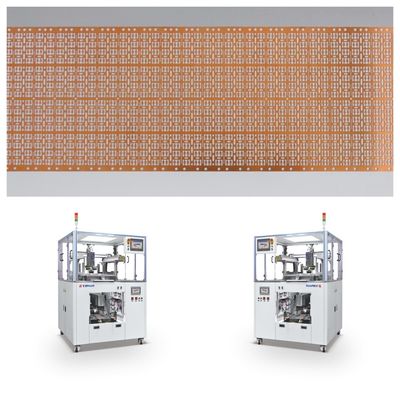

We take pride in our fully automatic molding system, which streamlines the molding process and eliminates the need for manual labor, saving both time and resources.

Our automatic encapsulation system guarantees a consistent and high-quality end product, meeting the strict standards of the semiconductor industry.

Choose our Semiconductor Molding Equipment for a reliable, efficient, and advanced solution for your semiconductor molding needs.

【Features】

● Semiconductor packaging equipment is also known as chip packaging equipment and IC packaging equipment, semiconductor MOLDING packaging equipment;

● Automatic packaging test chip, semiconductor device, IC and other products;

● Full servo control system, PLC (Omron)+upper machine;

● Win10+15 -inch touch screen+touch keyboard;

● CCD image detection, feeding anti -counter -detection;

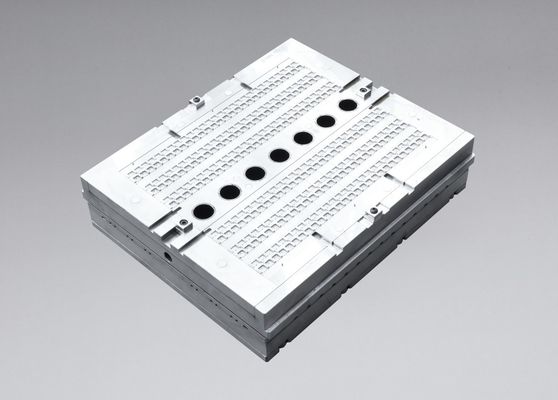

● Standardized mold structure, convenient replacement;

● High -efficient ingredients, cakes, mixing components, aluminum boxes;

● Support up to up to 4 sets of pressure machines to expand flexibly to achieve high UPH;

● Equipped with visual system recognition direction;

● Automatically enter the box, double -receiving box stacked collection;

● Select the molding function, the function of isolation, the detection function after packaging, etc.;

● Customized on demand, advanced technology, high equipment accuracy, stable performance, ensuring quality, and providing high -quality services permanently.

Technical Parameters:

| Technical Parameters |

Description |

| Energy Consumption |

Low |

| Control System |

PLC |

| Automation |

Fully Automated |

| Safety Features |

Advanced |

| Application |

Semiconductor Industry |

| Pressure Control |

Precision Pressure Control |

| Cycle Time |

Short |

| Temperature Control |

Precision Temperature Control |

| Capacity |

High |

| Product Type |

Molding Equipment |

Fully Automatic Molding System: This molding equipment is fully automated, providing efficient and precise production processes for the semiconductor industry.

Automatic Molding Press: With advanced PLC control system, this equipment is capable of producing high-quality products with precision pressure and temperature control.

Automatic Molding Presses: The fully automated process greatly reduces cycle time, increasing production capacity and reducing energy consumption for a more cost-effective solution.

Applications:

Product Description

The Semiconductor Molding Equipment, also known as TJIN 002, is a state-of-the-art automatic encapsulation system designed for the semiconductor production industry. With its precision temperature and pressure control, it is the perfect solution for molding plastic materials used in the production of semiconductors.

Application

The TJIN 002 is widely used in the semiconductor industry for its efficient and reliable performance. It is ideal for encapsulating delicate electronic components with plastic materials, ensuring their protection and durability during the manufacturing process.

Scene Scenario

The automatic molding machine operates in a temperature and humidity-controlled environment, mimicking the conditions needed for semiconductor production. The machine is placed in a cleanroom, and the operator wears protective gear to prevent any contamination during the encapsulation process.

The semiconductor components are loaded into the machine, and the precision temperature control ensures that the plastic material is heated to the exact temperature needed for encapsulation. The precision pressure control then applies the right amount of pressure to mold the plastic material around the component, creating a perfect seal.

Once the cycle time is complete, the encapsulated components are ejected from the machine, ready for the next stage of the semiconductor production process.

Product Features

- Brand Name: TJIN

- Model Number: 002

- Place of Origin: China

- Temperature Control: Precision Temperature Control

- Cycle Time: Short

- Material: Plastic

- Maintenance: Easy

- Pressure Control: Precision Pressure Control

Advantages

- The automatic encapsulation system ensures consistent and precise temperature and pressure control, resulting in high-quality encapsulated components.

- The short cycle time increases efficiency and reduces production time.

- The machine is made with high-quality materials and is easy to maintain, making it a cost-effective solution for semiconductor production.

- The precision temperature and pressure control ensure the safety and reliability of the encapsulated components.

Conclusion

The TJIN 002 Semiconductor Molding Equipment is the perfect solution for the semiconductor production industry. With its automatic encapsulation system and precision temperature and pressure control, it ensures the quality and efficiency needed for successful semiconductor production. Its ease of maintenance and reliable performance make it a valuable addition to any semiconductor production facility.

Customization:

TJIN Semiconductor Molding Equipment Customization Service

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Material: Plastic

Precision: High

Pressure Control: Precision Pressure Control

Temperature Control: Precision Temperature Control

Energy Consumption: Low

Introducing TJIN's custom plasticizing press service for our Semiconductor Molding Equipment. Our automatic molding machine, equipped with a plasticizing press unit, guarantees high precision and low energy consumption for all your molding needs.

With our intelligent control system, you can expect precise pressure and temperature control during the molding process, ensuring the best quality of finished products. Made with high-quality plastic material, our equipment is durable and reliable, making it the perfect choice for your semiconductor molding needs.

Trust TJIN for all your semiconductor molding needs and experience the benefits of our personalized and efficient service. Contact us today to learn more about our customization options and how we can help you achieve your molding goals.

Packing and Shipping:

Package and Shipping for Semiconductor Molding Equipment

Our Semiconductor Molding Equipment is carefully packaged and shipped to ensure safe delivery to our customers. Here is the breakdown of our packaging and shipping process:

Packaging

- The equipment is first wrapped in a protective layer of bubble wrap to prevent any damage during transportation.

- It is then placed in a sturdy cardboard box with additional cushioning material to provide extra protection.

- The box is sealed and labeled with the necessary shipping information, including the customer's address and tracking number.

- If necessary, the equipment may also be secured in a wooden crate for added protection.

Shipping

We offer various shipping options to meet our customers' needs:

- Standard shipping - Our default shipping method, which typically takes 3-5 business days for domestic deliveries.

- Expedited shipping - For customers who need their equipment delivered urgently, we offer expedited shipping options at an additional cost.

- International shipping - We ship worldwide and provide necessary documentation for customs clearance.

Once the equipment has been shipped, we provide our customers with a tracking number so they can monitor the delivery status. Our team also closely monitors the shipment to ensure timely and successful delivery.

At Semiconductor Molding Equipment, we prioritize the safety and timely delivery of our products. That's why we take great care in our packaging and shipping process to ensure customer satisfaction.

FAQ:

- Q: What is the brand name of this product?

A: The brand name is TJIN.

- Q: What is the model number of this product?

A: The model number is 002.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: What type of equipment is this?

A: This is a semiconductor molding equipment.

- Q: What are the main features of this product?

A: Some of the main features include high precision molding, efficient cooling system, and user-friendly interface.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!