Auto Chip Encapsulation System

Technical Parameters:

| Attribute |

Value |

| Product Type |

Molding Equipment |

| Application |

Semiconductor Industry |

| Precision |

High |

| Control System |

PLC |

| Temperature Control |

Precision Temperature Control |

| Automation |

Fully Automated |

| Molding Method |

Injection Molding |

| Energy Consumption |

Low |

| Pressure Control |

Precision Pressure Control |

| Cycle Time |

Short |

| Key Features |

Descriptions |

| Fully Automatic Molding System |

This molding equipment is equipped with a fully automatic system, allowing for efficient and convenient operation. |

| Automatic Molding Machine |

This machine can automatically carry out the molding process, saving time and effort for the user. |

| Automatic Molding Machine |

This molding equipment is specifically designed for use in the semiconductor industry, ensuring high precision results. |

Applications:

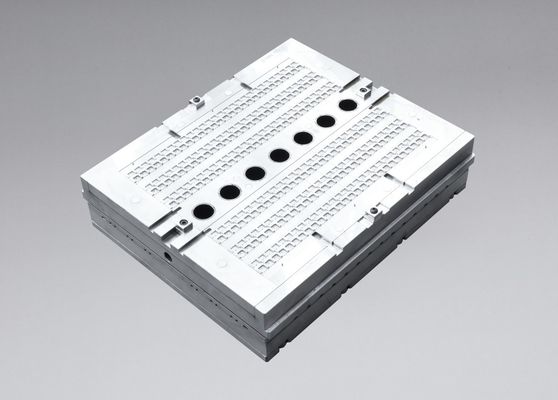

Semiconductor Molding Equipment - TJIN 002

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Temperature Control: Precision Temperature Control

Energy Consumption: Low

Pressure Control: Precision Pressure Control

Maintenance: Easy

Material: Plastic

The TJIN 002 Semiconductor Molding Equipment is an advanced and efficient product designed specifically for the semiconductor manufacturing industry. With its fully automatic encapsulation system, this molding equipment offers high precision and high efficiency in the production process.

Application

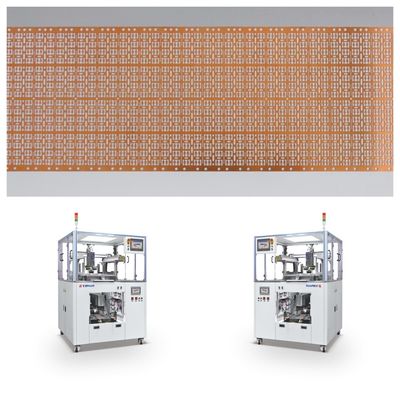

The TJIN 002 Semiconductor Molding Equipment is suitable for a wide range of applications in the semiconductor industry. Its automatic encapsulation system makes it ideal for mass production of semiconductor components such as integrated circuits, transistors, and diodes.

Scene 1: Semiconductor Manufacturing Facility

In a semiconductor manufacturing facility, the TJIN 002 Semiconductor Molding Equipment is used to produce high-quality, precision molded components. With its fully automatic molding system, the equipment can handle large quantities of plastic material and produce consistent results with minimal human intervention.

The precision temperature control feature ensures that the plastic material is heated to the optimal temperature for molding, while the precision pressure control feature ensures that the right amount of pressure is applied during the molding process. This results in high-quality, defect-free components.

The low energy consumption of the TJIN 002 Semiconductor Molding Equipment also makes it a cost-effective choice for semiconductor manufacturers, helping them save on production costs.

Scene 2: Research and Development Laboratory

In a research and development laboratory, the TJIN 002 Semiconductor Molding Equipment is used to test and develop new semiconductor components. The high precision and efficiency of the equipment allow researchers to quickly produce prototypes and test their functionality.

With its easy maintenance feature, the equipment can be easily cleaned and maintained, ensuring that it is always ready for use in the laboratory. And with its ability to mold plastic materials, researchers can experiment with different materials and find the best combination for their semiconductor components.

Conclusion

The TJIN 002 Semiconductor Molding Equipment is a top-of-the-line product that offers high precision, efficiency, and ease of maintenance. Its automatic encapsulation system, fully automatic molding system, and low energy consumption make it an ideal choice for semiconductor manufacturers and research laboratories. With this equipment, the production of high-quality semiconductor components becomes faster, easier, and more cost-effective.

Customization:

TJIN Semiconductor Molding Equipment Customized Service

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Precision: High

Capacity: High

Maintenance: Easy

Control System: PLC

Safety Features: Advanced

Our company, TJIN, specializes in providing customized services for our Automatic Encapsulation System, Automatic Molding Machine, and Automatic Molding Machine for Semiconductors. Our high precision and high capacity machines are designed and manufactured in China, making them both reliable and cost-effective.

With our easy maintenance and advanced safety features, our customers can trust in the quality and durability of our products. Our control system utilizes PLC technology, ensuring efficient and reliable operation.

At TJIN, we understand the importance of meeting the unique needs and specifications of our clients in the semiconductor industry. That's why we offer personalized customization services to meet your exact requirements. Our team of experts will work closely with you to design and develop a tailor-made solution that meets your specific production needs.

Choose TJIN for your Semiconductor Molding Equipment needs and experience the benefits of our top-of-the-line products and exceptional customized service. Contact us today to learn more!

Packing and Shipping:

Packaging and Shipping of Semiconductor Molding Equipment

Our Semiconductor Molding Equipment is carefully packaged to ensure safe and secure delivery to our customers. Depending on the size and weight of the equipment, it will be packaged in either wooden crates or heavy-duty cardboard boxes.

All electronic components are protected with anti-static packaging materials to prevent any potential damage during shipping. The equipment is also secured with foam padding and bubble wrap to further cushion it during transport.

For international shipping, we use a combination of air and sea freight to deliver our products to our customers. Each shipment is carefully tracked and monitored to ensure timely delivery and to provide our customers with updates on the status of their order.

Upon arrival at the destination, our customers will be responsible for any customs clearance procedures and fees. We will provide all necessary documentation to assist with the process.

If there are any special packaging or shipping requests, please inform us at the time of purchase so that we can accommodate your needs.

Thank you for choosing our Semiconductor Molding Equipment. We strive to provide the best packaging and shipping service to ensure your complete satisfaction.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

- A: The model number of this product is 002.

- Q: Where is this product manufactured?

- A: This product is manufactured in China.

- Q: What is the function of this product?

- A: This product is used for molding semiconductors.

- Q: What is the working temperature of this product?

- A: The working temperature of this product is between 150-200 degrees Celsius.

- Q: Is this product suitable for mass production?

- A: Yes, this product is designed for high volume production of semiconductors.

【Features】

● Semiconductor plastic and sealing equipment is also called IC and chip plastic and sealing equipment.

● Full servo control system, PLC (Omron)+upper machine;

● Win10+15 -inch touch screen+touch keyboard;

● CCD image detection, feed anti -counter -anti -detection

● Standardized mold structure, convenient replacement;

● High -efficient ingredients, cakes, mixing components, aluminum boxes;

● Support up to up to 4 sets of pressure machines to expand flexibly to achieve high UPH;

● Equipped with visual system recognition direction;

● Customized on demand, advanced technology, responsible for installing, debugging and training, and providing high -quality services permanently.

【Performance parameters】

● Model pressure: 98-1764kn;

● injection molding pressure: 4.9-29.4kn can be adjusted;

● Applicable lead frame/substrate size: 20-90mm wide, 124-300mm long;

● Applicable plastic seal size: diameter φ 11 ~ 20mm, length 12 ~ 35mm;

Semiconductor plastic seal equipment is mainly used in TO, SOP, SSOP, TSSOP, DIP, SOT, ESOT, SOD, QFN, SMA, SMC, SMBF, MBF, JA, QFP, IPM, BGDFNOFP and other semiconductor devices, IC , The chip automatic plastic seal test.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!