Auto Chip Molding System

Technical Parameters:

| Parameter |

Value |

| Maintenance |

Easy |

| Control System |

PLC |

| Application |

Semiconductor Industry |

| Capacity |

High |

| Cycle Time |

Short |

| Safety Features |

Advanced |

| Molding Method |

Injection Molding |

| Precision |

High |

| Energy Consumption |

Low |

| Pressure Control |

Precision Pressure Control |

| Product Name |

Semiconductor Molding Equipment |

| Automatic Features |

Fully Automatic Molding System, Fully Automatic Molding System, Automatic Molding Machine |

| Maintenance |

Easy |

| Control System |

PLC |

| Application |

Semiconductor Industry |

| Capacity |

High |

| Cycle Time |

Short |

| Safety Features |

Advanced |

| Molding Method |

Injection Molding |

| Precision |

High |

| Energy Consumption |

Low |

| Pressure Control |

Precision Pressure Control |

Applications:

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Control System: PLC

Safety Features: Advanced

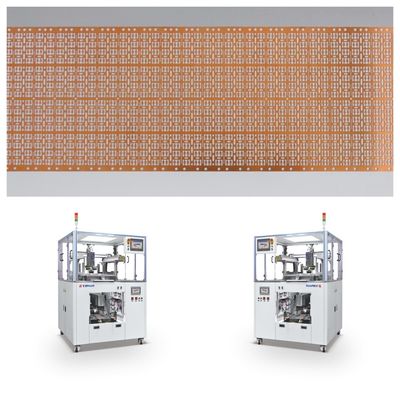

TJIN Semiconductor Molding Equipment is a cutting-edge product designed and manufactured in China by TJIN. It is a fully automatic molding system that uses advanced PLC control system to ensure high precision, high efficiency, and safe operation.

Product Type: Molding Equipment

Our product is specifically designed for the semiconductor industry, where precision and efficiency are crucial. It is a state-of-the-art molding equipment that can be used in various applications, including semiconductor packaging, LED packaging, and electronic component manufacturing.

Material: Plastic

The molding equipment is made of high-quality plastic material, ensuring durability and longevity. This makes it suitable for long-term use in demanding semiconductor manufacturing environments.

Capacity: High

With its fully automatic molding system, the TJIN Molding Equipment has a high production capacity, making it ideal for large-scale production in the semiconductor industry. It can produce a high volume of high-quality products in a short period, increasing efficiency and reducing production time.

Application Scenarios

Scenario 1: Semiconductor Packaging

Our molding equipment is widely used in semiconductor packaging, where it can produce high-precision and high-quality semiconductor packages. The intelligent control system ensures stability and flexibility, making it suitable for various semiconductor packaging designs.

Scenario 2: LED Packaging

In the LED industry, our molding equipment plays a crucial role in producing LED packages with high precision and efficiency. With its fully automatic molding system, it can handle different types and sizes of LED packages, meeting the diverse needs of the LED industry.

Scenario 3: Electronic Component Manufacturing

Our product is also ideal for electronic component manufacturing, where it can produce high-quality plastic components with precise dimensions. The safe operation and advanced safety features ensure the protection of both the equipment and the operators.

Key Features

Fully Automatic Molding System

The TJIN Molding Equipment is a fully automatic system, eliminating the need for manual labor and reducing the possibility of human errors. This increases efficiency and ensures consistent and high-quality production.

Automatic Molding Press

The automatic molding press allows for efficient and precise molding of plastic materials. It operates at high speeds, reducing production time and increasing output.

High Precision

With its advanced PLC control system and high-quality material, the TJIN Molding Equipment can achieve high precision in the molding process. This ensures the production of accurate and consistent products.

High Efficiency

The intelligent control system and fully automatic operation make our molding equipment highly efficient. It can produce a high volume of products in a short period, reducing production time and costs.

Intelligent Control

The intelligent control system allows for easy operation and monitoring of the molding process. It also has the capability to store and analyze production data, providing valuable insights for process improvement.

Stability and Flexibility

The TJIN Molding Equipment is designed to be stable and flexible, making it suitable for various molding requirements and designs. It can handle different types of plastic materials and produce a wide range of products.

Durability

Our product is made of high-quality plastic material, ensuring its durability and longevity. It can withstand the demands of the semiconductor industry and operate efficiently for a long period.

Safe Operation

The TJIN Molding Equipment is equipped with advanced safety features to ensure safe operation. It is designed to protect both the equipment and the operators, providing a safe working environment.

Customization:

TJIN Semiconductor Molding Equipment - Customized Service

Brand Name: TJIN

Model Number: 002

Place of Origin: China

Control System: PLC (Programmable Logic Controller)

Precision: High

Cycle Time: Short

Material: Plastic

Temperature Control: Precision Temperature Control

Key Features:

- Fully Automatic Molding System

- Automatic Encapsulation System

- Automatic Molding Machine

【Features】

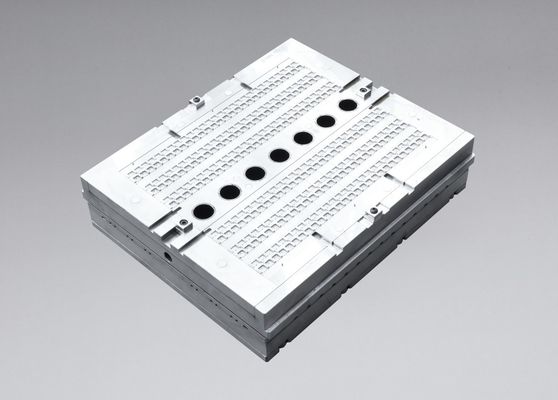

● Semiconductor packaging equipment is also known as chip packaging equipment and IC packaging equipment, semiconductor MOLDING packaging equipment;

● Automatic packaging test chip, semiconductor device, IC and other products;

● Full servo control system, PLC (Omron)+upper machine;

● Win10+15 -inch touch screen+touch keyboard;

● CCD image detection, feeding anti -counter -detection;

● Standardized mold structure, convenient replacement;

● High -efficient ingredients, cakes, mixing components, aluminum boxes;

● Support up to up to 4 sets of pressure machines to expand flexibly to achieve high UPH;

● Equipped with visual system recognition direction;

● Automatically enter the box, double -receiving box stacked collection;

● Select the molding function, the function of isolation, the detection function after packaging, etc.;

● Customized on demand, advanced technology, high equipment accuracy, stable performance, ensuring quality, and providing high -quality services permanently.

Semiconductor packaging equipment is mainly used in TO, SOP, SSOP, TSSOP, DIP, SOT, ESOT, SOD, QFN, SMA, SMC, SMBF, MBF, JA, QFP, IPM, BGAPDFNOFP and other semiconductor devices, IC , Chip one -stop automatic packaging test.

【Performance parameters】

● Model pressure: 98-1764kn;

● injection molding pressure: 4.9-29.4kn can be adjusted;

● Applicable lead frame/substrate size: 20-90mm wide, 124-300mm long;

● Applicable plastic seal size: diameter φ 11 ~ 20mm, length 12 ~ 35mm;

Packing and Shipping:

Packaging and Shipping for Semiconductor Molding Equipment

Our Semiconductor Molding Equipment is carefully packaged to ensure safe delivery to our customers. Each unit is packed in a sturdy wooden crate with foam padding to protect against any damage during transportation.

For international shipping, the equipment is securely strapped onto a pallet and wrapped with stretch film to prevent any shifting during transit.

We offer various shipping options to meet our customers' needs. Standard shipping is available for domestic and international orders, with estimated delivery times provided at the time of purchase. We also offer expedited shipping for urgent orders.

Our team carefully inspects each unit before packaging to ensure that it is in perfect working condition. We also include all necessary manuals and documentation with each shipment.

Please note that any additional fees or taxes associated with customs clearance are the responsibility of the customer.

Thank you for choosing our Semiconductor Molding Equipment. We are committed to providing a seamless and secure shipping experience for our customers.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

- A: The model number of this product is 002.

- Q: Where is this product manufactured?

- A: This product is manufactured in China.

- Q: What type of equipment is Semiconductor Molding Equipment?

- A: Semiconductor Molding Equipment is a type of industrial equipment.

- Q: What is the function of Semiconductor Molding Equipment?

- A: The function of Semiconductor Molding Equipment is to mold semiconductors into specific shapes and sizes.

- Q: Is this product suitable for mass production?

- A: Yes, this product is designed for mass production of semiconductors.

- Q: Does this product require specialized training to operate?

- A: Yes, operators of this product should receive proper training to ensure safe and efficient operation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!