Auto Mold System

Features

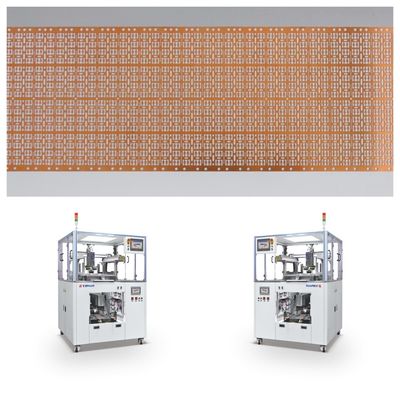

● Automatic molding press also known as automatic molding machine, automatic molding chips, semiconductor devices and other products;

● Full servo control system, PLC (Omron) + controller;

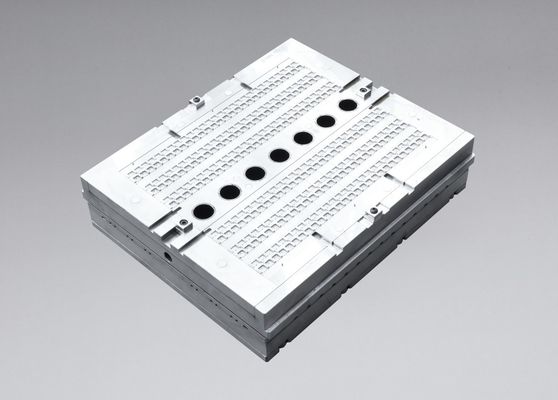

● Standardized mold structure, easy to change;

● High efficiency cake loading component, aluminum box loading;

● Automatic cassette loading, double cassette stacked loading;

● Supports flexible expansion of up to 4 groups of presses to realize high UPH;

● Equipped with vision system to recognize the feeding direction;

● WIN10 + 15 inch touch screen + touch keyboard;

● CCD image detection, feeding anti-reverse detection;

● Optional mold vacuum function, isolation mold function, detection function after plastic sealing;

● Use of imported raw materials, high precision, stable performance, high service life, quality assurance;

● Customized on demand, permanently provide quality service.

Technical Parameters:

| Type |

Vertical Injection Molding Machine |

| Control System |

PLC |

| Model |

SM-1000 |

| Cooling System |

Water |

| Weight |

5 Tons |

| Clamping Force |

1000KN |

| Capacity |

100 Tons |

| Screw Diameter |

35 Mm |

| Max. Mold Height |

400Mm |

| Injection Pressure |

200 Mpa |

| Auto Transfer Molding |

Yes |

| Auto Packaging Equipment |

Yes

|

Performance Parameters

● Mold closing pressure: 98-1764kN;

● Injection pressure: 4.9-30kN adjustable;

● Applicable leadframe/substrate size: width 20-90mm, length 100-300mm, thickness 0.15-1.2mm;

● Applicable molding material size: diameter φ 11-20mm, length/diameter 1.2-2.0 (Max 35mm).

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

- A: The model number of this product is 001.

- Q: Where is this product made?

- A: This product is made in China.

- Q: Does this product have any certifications?

- A: Yes, this product is ISO9001 certified.

- Q: What is the minimum order quantity for this product?

- A: The minimum order quantity for this product is 1.

- Q: How is this product packaged?

- A: This product is packaged in wooden packaging.

- Q: What is the estimated delivery time for this product?

- A: The estimated delivery time for this product is 40 days.

- Q: What are the payment terms for this product?

- A: The payment terms for this product are TT (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!