PRODUCT ADVANTAGES

1. High product precision

2. Professional precision manufacturing and long mold life

3. Food packaging hardware punching and cutting molds

Customization:

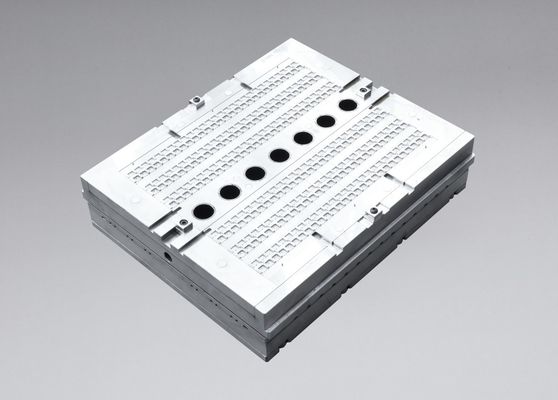

TJIN - IC Lead Frame Stamping Mold Customization Service

Brand Name: TJIN

Model Number: 006

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1

Packaging Details: Wooden Packaging

Delivery Time: 40 days

Payment Terms: TT

Application: IC Lead Frame Stamping

Runner System: Hot Runner/Cold Runner

Cavity Number: Single

Tolerance: ±0.01mm

Mold Cooling System: Water Cooling

Hige-Quality Lead Frame Mold

Semicon IC Lead Frame Mold

Packing and Shipping:

IC Lead Frame Stamping Mold Packaging and Shipping

Thank you for choosing our IC Lead Frame Stamping Mold! We are committed to providing you with high-quality products and excellent service.

Packaging

Our IC Lead Frame Stamping Mold will be carefully packaged to ensure its safe delivery to you. The packaging will include:

- Sturdy cardboard box or crate

- Bubble wrap or foam padding

- Protective plastic wrapping

- Product manual or instructions

These materials will protect the mold from any damage during transit.

Shipping

We offer several shipping options to meet your needs:

- Standard shipping: Estimated delivery within 5-7 business days

- Expedited shipping: Estimated delivery within 2-3 business days

- International shipping: Estimated delivery time varies by location

Once your order is processed, you will receive a tracking number via email to track your shipment.

Please note that shipping costs may vary depending on the shipping method and your location.

Customs and Duties

For international orders, please be aware that customs and duties may apply. These fees are the responsibility of the customer and are not included in the product price or shipping cost.

If you have any questions or concerns about the packaging or shipping of our IC Lead Frame Stamping Mold, please don't hesitate to contact us. Thank you again for choosing our product.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 006.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: Does this product have any certification?

A: Yes, this product is certified with ISO9001.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1.

- Q: How is this product packaged for delivery?

A: This product is packaged in wooden packaging.

- Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 40 days.

- Q: What are the available payment terms for this product?

A: The available payment terms for this product are TT (Telegraphic Transfer).

【Features】

1. Has high -precision and high strength and other characteristics

2. Professional precision manufacturing molds have high abrasion resistance with high life span

3. Material: Imported raw materials

4. Accuracy: Gensory value reaches ± 0.001mm

5. Small degrees: The line cut uses the original Japanese SODICK GF scheme electrode wire to ensure good surface smoothness.

6. Careful service: source manufacturer supply, quality and low price, intimate after -sales, no worry -free after -sales;

7. Guarantee quality: reliable quality, integrity operation, multiple specifications, delivery on time;

8. Customized according to the specific needs of customers

Technical Parameters:

| IC Lead Frame Stamping Mold Technical Parameters |

| Mold Life |

100,000 Shots |

| Mold Cooling System |

Water Cooling |

| Application |

IC Lead Frame Stamping |

| Surface Treatment |

Nickel Plating |

| Lead Time |

4-6 Weeks |

| Runner System |

Hot Runner/Cold Runner |

| Mold Material |

NAK80, S136, SKD61, Etc. |

| Cavity Number |

Single |

| Mold Type |

Stamping Mold |

| Mold Base |

LKM, DME, HASCO, Etc. |

| IC Lead Frame Stamping Mold Features |

| Hige-Quality Lead Frame Mold |

This mold is made with high-quality materials and precision manufacturing techniques to ensure the best performance and longevity. |

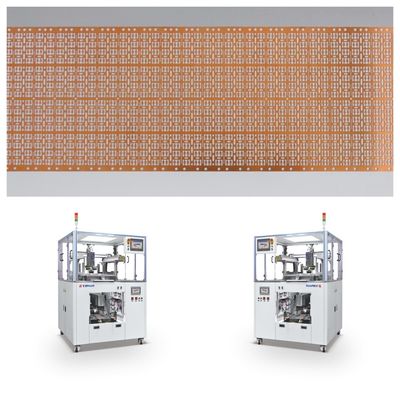

| Semicon IC Lead Frame Mold |

Specifically designed for the production of semiconductor IC lead frames, this mold provides high precision and efficiency. |

| Lead Frame Mold |

This mold is designed to create lead frames for electronic components, making it an essential tool in the electronics industry. |

| IC Lead Frame Stamping Mold |

The stamping process allows for high-speed and high-volume production of IC lead frames, making this mold ideal for mass production. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!