Applications:

Semiconductor Molding Machine - TJIN 001

Product Description

The Semiconductor Molding Machine by TJIN is a high-quality and efficient machine designed for use in the production of semiconductors. With a sturdy construction and advanced technology, this machine is perfect for any production facility looking to improve their molding process.

Brand Name

The brand name of this product is TJIN, a trusted and well-known name in the manufacturing industry.

Model Number

The model number of this machine is 001, indicating its advanced and innovative design.

Place of Origin

This product is proudly made in China, known for its high-quality manufacturing and technological advancements.

Certification

This machine has been certified with ISO9001, ensuring its quality and reliability.

Minimum Order Quantity

The minimum order quantity for this product is 1, making it accessible for both small and large scale production facilities.

Packaging Details

The machine is packed in a sturdy wooden packaging, ensuring its safe transport and delivery.

Delivery Time

The average delivery time for this product is 40 days, ensuring a timely and efficient delivery process.

Payment Terms

The payment terms for this product is TT, making it convenient for customers to make payment.

Screw Diameter

The screw diameter of this machine is 35mm, allowing for precise and efficient molding of semiconductors.

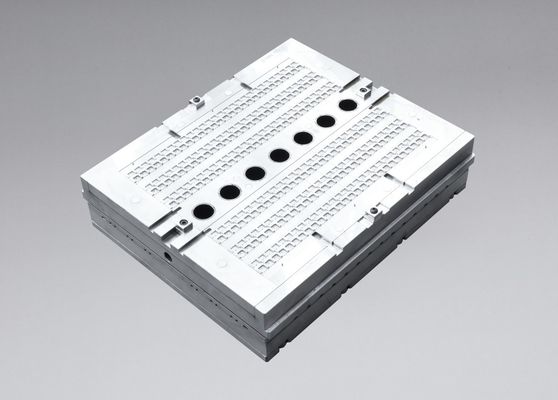

Platen Size

The platen size of this machine is 600 x 600mm, providing ample space for large-scale production.

Control System

The control system of this machine is equipped with a PLC, allowing for easy and accurate control of the molding process.

Capacity

With a capacity of 100 tons, this machine can handle high volumes of production without compromising on quality.

Injection Unit

The injection unit of this machine is single, ensuring a streamlined and efficient molding process.

Features

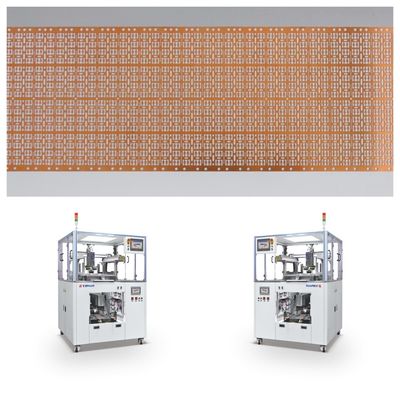

● Automatic molding press also known as automatic molding machine, automatic molding chips, semiconductor devices and other products;

● Full servo control system, PLC (Omron) + controller;

● Standardized mold structure, easy to change;

● High efficiency cake loading component, aluminum box loading;

● Automatic cassette loading, double cassette stacked loading;

● Supports flexible expansion of up to 4 groups of presses to realize high UPH;

● Equipped with vision system to recognize the feeding direction;

● WIN10 + 15 inch touch screen + touch keyboard;

● CCD image detection, feeding anti-reverse detection;

● Optional mold vacuum function, isolation mold function, detection function after plastic sealing;

● Use of imported raw materials, high precision, stable performance, high service life, quality assurance;

Technical Parameters:

| Type |

Vertical Injection Molding Machine |

| Control System |

PLC |

| Model |

SM-1000 |

| Cooling System |

Water |

| Weight |

5 Tons |

| Clamping Force |

1000KN |

| Capacity |

100 Tons |

| Screw Diameter |

35 Mm |

| Max. Mold Height |

400Mm |

| Injection Pressure |

200 Mpa |

| Auto Transfer Molding |

Yes |

| Auto Packaging Equipment |

Yes

|

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

- A: The model number of this product is 001.

- Q: Where is this product made?

- A: This product is made in China.

- Q: Does this product have any certifications?

- A: Yes, this product is ISO9001 certified.

- Q: What is the minimum order quantity for this product?

- A: The minimum order quantity for this product is 1.

- Q: How is this product packaged?

- A: This product is packaged in wooden packaging.

- Q: What is the estimated delivery time for this product?

- A: The estimated delivery time for this product is 40 days.

- Q: What are the payment terms for this product?

- A: The payment terms for this product are TT (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!