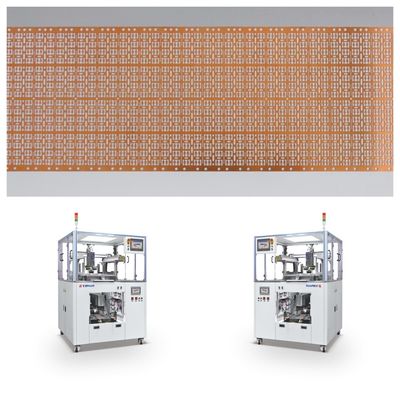

Auto Plasticizing Press

Product Details:

● WIN10 + 15 inch touch screen + touch keyboard;

● CCD image detection, feeding anti-reverse detection;

● Optional mold vacuum function, isolation mold function, detection function after plastic sealing;

● Use of imported raw materials, high precision, stable performance, high service life, quality assurance;

● Customized on demand, permanently provide quality service.

Customization:

Customized Service for Semiconductor Molding Machine - TJIN Model 001

Brand Name: TJIN

Model Number: 001

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1

Packaging Details: Wooden Packaging

Delivery Time: 40 days

Payment Terms: TT

Heating Power: 12 KW

Cooling System: Water

Model: SM-1000

Clamping Force: 1000 KN

Weight: 5 Tons

At TJIN, we understand the unique needs of the semiconductor industry and are committed to providing the best customized service for our customers. Our Semiconductor Molding Machine, model 001, is designed with the latest technology and high-quality materials to ensure efficient and precise molding of semiconductor products.

Our auto packaging equipment and auto transfer molding capabilities allow for a seamless and efficient production process. With our state-of-the-art equipment and experienced technicians, we guarantee superior quality and consistency in every product.

As a reputable manufacturer in China, we hold an ISO9001 certification, ensuring that our products meet the highest standards of quality and reliability. With a minimum order quantity of 1 and a delivery time of 40 days, we offer flexibility and timely delivery to meet your production needs.

For safe transportation, our products are packaged in sturdy wooden packaging. We also offer various payment terms, including TT, to accommodate our customers' preferences.

With a heating power of 12 KW and a cooling system that uses water, our SM-1000 model is perfect for molding semiconductors. It has a clamping force of 1000 KN and weighs 5 tons, making it a powerful and durable machine.

Choose TJIN for your semiconductor molding needs, and experience exceptional quality, customization, and service. Contact us today for more information or to place an order.

Packing and Shipping:

Packaging and Shipping

The Semiconductor Molding Machine is carefully packaged to ensure safe delivery to our valued customers. Each machine is first wrapped in protective materials to prevent any damage during transportation.

We use high-quality and durable materials for our packaging, such as sturdy cardboard boxes and foam inserts. This ensures that the machine is well-protected and secure during shipping.

Our shipping process is efficient and timely, with options for both domestic and international delivery. We work with trusted carriers to ensure the fastest and most reliable delivery of our products.

Upon delivery, our customers can expect to receive the machine in excellent condition, ready to be installed and put to use. We also provide detailed instructions and support for installation and operation to ensure a smooth and successful setup.

We take great care in packaging and shipping our Semiconductor Molding Machine, so our customers can have peace of mind knowing their product will arrive safely and ready to use.

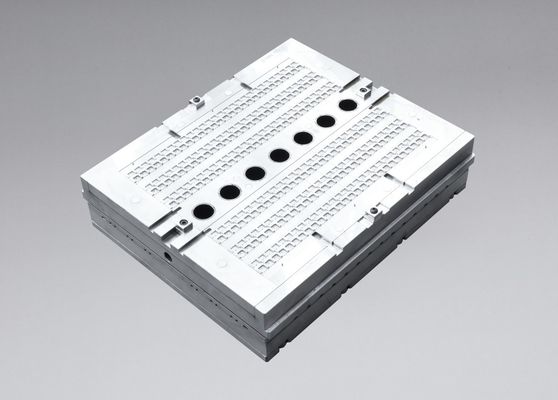

Performance Parameters:

● Mold closing pressure: 98-1764kN;

● Injection pressure: 4.9-30kN adjustable;

● Applicable leadframe/substrate size: width 20-90mm, length 100-300mm, thickness 0.15-1.2mm;

● Applicable molding material size: diameter φ 11-20mm, length/diameter 1.2-2.0 (Max 35mm).

Technical Parameters:

| Max. Mold Height: |

400 mm |

| Clamping Force: |

1000 kN |

| Injection Pressure: |

200 MPa |

| Screw Diameter: |

35 mm |

| Cooling System: |

Water |

| Control System: |

PLC |

| Type: |

Vertical Injection Molding Machine |

| Heating Power: |

12 kW |

| Platen Size: |

600 x 600 mm |

| Capacity: |

100 tons |

| Auto Packaging Equipment |

Yes |

| Auto Transfer Molding |

Yes |

| Auto Packaging Equipment |

Yes |

Packing and Shipping:

Packaging and Shipping

The Semiconductor Molding Machine is carefully packaged to ensure safe delivery to our valued customers. Each machine is first wrapped in protective materials to prevent any damage during transportation.

We use high-quality and durable materials for our packaging, such as sturdy cardboard boxes and foam inserts. This ensures that the machine is well-protected and secure during shipping.

Our shipping process is efficient and timely, with options for both domestic and international delivery. We work with trusted carriers to ensure the fastest and most reliable delivery of our products.

Upon delivery, our customers can expect to receive the machine in excellent condition, ready to be installed and put to use. We also provide detailed instructions and support for installation and operation to ensure a smooth and successful setup.

We take great care in packaging and shipping our Semiconductor Molding Machine, so our customers can have peace of mind knowing their product will arrive safely and ready to use.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 001.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: Is this product certified?

A: Yes, this product is certified with ISO9001.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 unit.

- Q: How is this product packaged?

A: This product is packaged in wooden packaging.

- Q: How long is the delivery time for this product?

A: The delivery time for this product is 40 days.

- Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are TT (Telegraphic Transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!