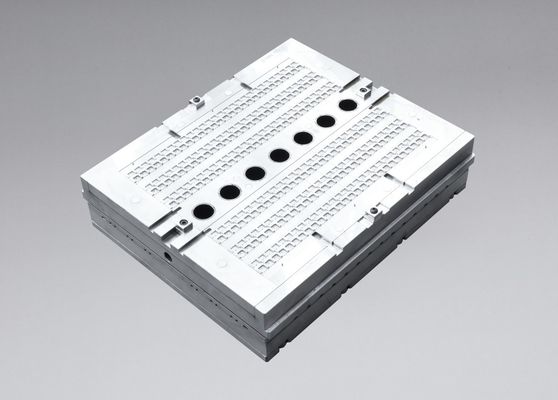

TJIN Semiconductor Technology Company, professional R & D and manufacturing IC -lead framework molds, all are customized as needed, advanced technology, using imported raw materials, high mold accuracy, stable performance, high life life, reasonable price, guarantee quality, and worry -free after -sales.

Technical Parameters:

| IC Lead Frame Stamping Mold Technical Parameters |

| Mold Life |

100,000 Shots |

| Mold Cooling System |

Water Cooling |

| Application |

IC Lead Frame Stamping |

| Surface Treatment |

Nickel Plating |

| Lead Time |

4-6 Weeks |

| Runner System |

Hot Runner/Cold Runner |

| Mold Material |

NAK80, S136, SKD61, Etc. |

| Cavity Number |

Single |

| Mold Type |

Stamping Mold |

| Mold Base |

LKM, DME, HASCO, Etc. |

| IC Lead Frame Stamping Mold Features |

| Hige-Quality Lead Frame Mold |

This mold is made with high-quality materials and precision manufacturing techniques to ensure the best performance and longevity. |

| Semicon IC Lead Frame Mold |

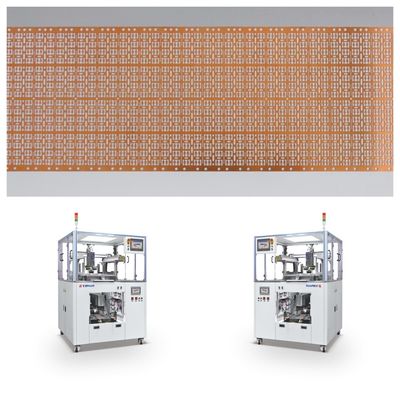

Specifically designed for the production of semiconductor IC lead frames, this mold provides high precision and efficiency. |

| Lead Frame Mold |

This mold is designed to create lead frames for electronic components, making it an essential tool in the electronics industry. |

| IC Lead Frame Stamping Mold |

The stamping process allows for high-speed and high-volume production of IC lead frames, making this mold ideal for mass production.

|

Customization:

IC Lead Frame Stamping Mold Customization Service for TJIN

Brand Name: TJIN

Model Number: 006

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1

Packaging Details: Wooden Packaging

Delivery Time: 40 days

Payment Terms: TT

Mold Size: Customized

Hardness: HRC 50-60

Mold Type: Stamping Mold

Mold Base: LKM, DME, HASCO, Etc.

Tolerance: ±0.01mm

At TJIN, we offer customized services for our IC Lead Frame Stamping Mold to meet the specific needs of our clients. Our Semicon IC Lead Frame Mold is designed with precision and is suitable for various applications in the semiconductor industry. We understand the importance of customization and strive to provide high-quality solutions that meet the unique requirements of our customers.

Packing and Shipping:

IC Lead Frame Stamping Mold Packaging and Shipping

The IC Lead Frame Stamping Mold is carefully packaged to ensure safe delivery to our customers. The mold is first wrapped in protective materials, such as bubble wrap or foam, to prevent any damage during transit. It is then placed in a sturdy cardboard box with additional padding to further protect it.

The package is labeled with the product name and description, as well as any necessary handling instructions. We also include a packing slip with the customer's order information for easy identification.

For shipping, we use trusted and reliable shipping carriers to ensure timely and secure delivery. Customers can choose from a variety of shipping options based on their location and preferred delivery speed.

With our careful packaging and efficient shipping methods, we guarantee that our IC Lead Frame Stamping Mold will arrive at your doorstep in perfect condition.

FAQ:

- Q: What is the brand name of this product?

A: The brand name is TJIN.

- Q: What is the model number of this product?

A: The model number is 006.

- Q: Where is this product made?

A: This product is made in China.

- Q: Does this product have any certifications?

A: Yes, it is certified with ISO9001.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 1.

- Q: How is this product packaged?

A: It is packaged in wooden packaging.

- Q: How long is the delivery time for this product?

A: The delivery time is 40 days.

- Q: What are the payment terms for this product?

A: The payment terms are TT (telegraphic transfer).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!