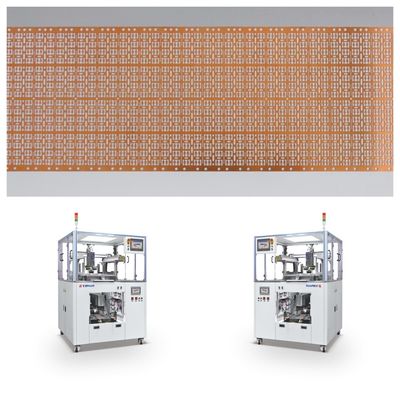

Fully automatic cam synchronized high -speed tendon molding system

Automatic Punching and Forming System

PRODUCT ADVANTAGES:

1. Using imported raw materials, utilizing imported advanced equipment for manufacturing and testing, the equipment has high precision and stable performance;

2. Customized according to the needs of strong wear resistance, high service life, quality assurance, after-sales worry-free.

Applications:

TJIN 003 Trim And Form Machine

| Brand Name |

TJIN |

| Model Number |

003 |

| Place of Origin |

China |

| Forming Size |

Max. 110mm X 110mm |

| Trimming Size |

Max. 110mm X 110mm |

| Control System |

PLC Control System |

| Weight |

Approx. 500kg |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

Customization:

Customized Services for TJIN Trim And Form Machine

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Operation Mode: Manual/Auto

Trimming Speed: Approx. 0.5 Seconds Per Piece

Air Consumption: Approx. 100L/min

Forming Speed: Approx. 0.8 Seconds Per Piece

Weight: Approx. 500kg

Introducing TJIN's customized services for our innovative Trim And Form Machine. Designed and manufactured in China, this Auto Trim & Form System is the perfect solution for your semiconductor cutting and molding needs.

Our Tendon cutting and molding machine offers a manual and automatic operation mode, providing flexibility and ease of use for your production process. With a trimming speed of approximately 0.5 seconds per piece and a forming speed of approximately 0.8 seconds per piece, our machine guarantees efficiency and precision in every trim and form.

With an air consumption of approximately 100L/min, our machine is environmentally friendly and cost-effective. Weighing in at approximately 500kg, our Trim And Form Machine is compact and easy to install in any production line.

Choose TJIN for all your Trim And Form Machine needs and experience our top-notch customized services. Trust us to deliver the best quality, speed, and efficiency for your semiconductor cutting and molding process.

Technical Parameters:

| Product Name |

Trim And Form Machine |

| Model |

Auto Trim & Form System |

| Application |

Semiconductor Cutting and Molding Machine |

| Trimming Size |

Max. 110mm X 110mm |

| Forming Size |

Max. 110mm X 110mm |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| Trimming Speed |

Approx. 0.5 Seconds Per Piece |

| Power Supply |

AC 220V, 50/60Hz |

| Air Pressure |

0.5MPa |

| Air Consumption |

Approx. 100L/min |

| Power Consumption |

Approx. 1.5kW |

| Weight |

Approx. 500kg |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Additional Features |

Auto Frame Loader |

Main Product Features:

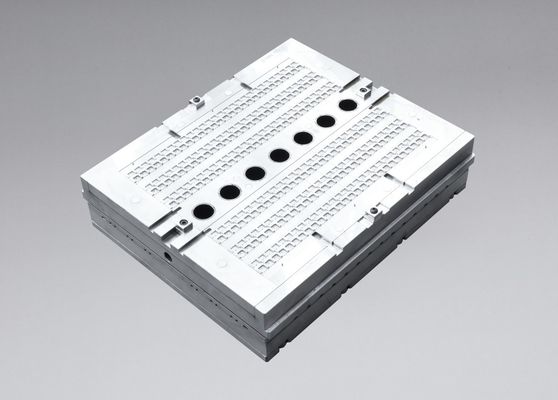

Equipment Function: Cutting, bending, separating and collecting the plasticized products;

Punching speed: 120-180 punches / minute (SPM: 120-180)

Applicable packages: SOT / SOD / TSOT / SOP / SSOP / TSSOP / MSOP and other series.

Punching power: servo motor upper power-3~5T;

Control system: PLC (Omron)

Operating system: touch screen + operation buttons, display UPH/SPM punching and cutting number counting function ;Â

Detection system: feeding and discharging double-mirror CCD image detection.

Feeding mechanism: rotary double magazines feeding.

Receiving mechanism: material box receiving (bulk)

Safety protection system: the equipment is equipped with leakage protection device, emergency stop button device and all the main door guards are equipped with SENSOR protection device, after the door guard is opened, the system should make certain reaction to protect personal safety;

Option 1: CCD visual inspection device;

Option 2: MES system networking function;

Packing and Shipping:

Trim And Form Machine - Packaging and Shipping

The Trim And Form Machine will be carefully packaged and shipped to ensure its safe arrival. Each machine will be wrapped in protective material and placed in a sturdy box. The box will then be sealed and labeled with the necessary shipping information.

For domestic shipments within the United States, the machine will be shipped via ground shipping with a reputable carrier. For international shipments, the machine will be shipped via air freight with proper documentation and customs clearance.

Customers can also opt for expedited shipping at an additional cost, which will be calculated based on the destination and desired delivery speed.

Upon shipment, customers will receive a tracking number to track the delivery of their Trim And Form Machine. We strive to ensure timely and secure delivery of our products to our valued customers.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product made?

A: This product is made in China.

- Q: What is the function of this product?

A: This product is a trim and form machine, used for trimming and forming electronic components.

- Q: What is the power source of this product?

A: The power source of this product is electricity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!