Automatic Tendon Cutting and Forming Machine

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product made?

A: This product is made in China.

- Q: What is the function of this machine?

A: This machine is used for trimming and forming metal components.

- Q: What is the power source of this machine?

A: The power source of this machine is electricity.

Packing and Shipping:

Packaging and Shipping

Packaging

The Chip Sorting Machine will be packed in a sturdy cardboard box to ensure safe transport. The box will also be labeled with the product name and a detailed description of the contents.

Inside the box, the machine will be wrapped in bubble wrap and secured with foam inserts to prevent any damage during shipping. All necessary accessories and instruction manuals will also be included in the packaging.

We take great care in packaging our products and use only high-quality materials to ensure that the Chip Sorting Machine arrives at its destination in perfect condition.

Shipping

We offer worldwide shipping for our Chip Sorting Machine. We work with reputable shipping companies to ensure timely and safe delivery of our products to our customers.

For domestic orders, we offer standard ground shipping as well as expedited shipping options for an additional fee. For international orders, we offer standard air freight shipping. Customers may also choose to use their own preferred shipping method and provide us with the necessary details.

Once the order is processed and shipped, customers will receive a tracking number to monitor their shipment. We strive to deliver our products as quickly and efficiently as possible.

Please note that any additional taxes, customs duties, or fees incurred during shipping are the responsibility of the customer.

For any questions or concerns regarding packaging and shipping, please contact our customer service team. We are dedicated to providing the best service and ensuring that our customers receive their Chip Sorting Machine in perfect condition.

Main features

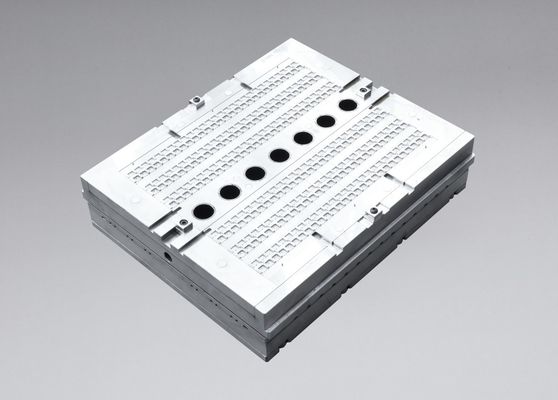

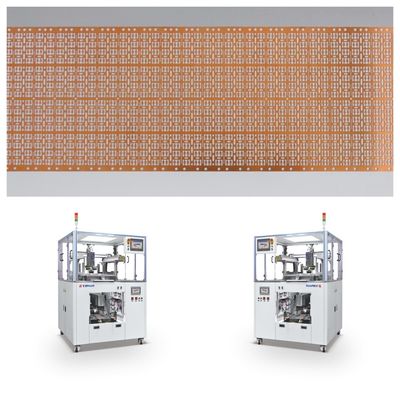

Function of the equipment: Cutting, bending and separating collection of products after plasticizing;

Punching speed: 50~100 punches/minute (SPM:50~100)

Applicable packages: SOP/SSOP/TSOP/MSOP/TSOP/TO/DIP series;

Punching power: servo motor upper power-3~5T.

Control system: PLC (Omron)

Operating system: touch screen + operating buttons, display UPH/SPM punching number counting function

Charging mechanism: automatic conversion of cascading tube tray for charging (tube loading)

Safety protection system: the equipment is equipped with leakage protection device, emergency stop button device and all the main door guards are equipped with SENSOR protection device, after the door guards are opened, the system should make a certain response to protect personal safety.

Option 1: CCD visual inspection device;

Option 2: MES system networking function;

- Product Name: Trim And Form Machine

- Forming Speed: Approx. 0.8 Seconds Per Piece

- Safety Features: Emergency Stop Button, Safety Light Curtain

- Power Consumption: Approx. 1.5kW

- Dimensions: Approx. 1,200mm X 1,200mm X 1,500mm

- Model: TFM-1100

- Semiconductor Tendon Cutting Machine

- Auto Frame Loader

- Trim and Form System

Technical Parameters:

| Semiconductor Cutting and Molding Machine |

|

| Model |

TFM-1100 |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Forming Size |

Max. 110mm X 110mm |

| Trimming Size |

Max. 110mm X 110mm |

| Air Pressure |

0.5MPa |

| Trimming Speed |

Approx. 0.5 Seconds Per Piece |

| Operation Mode |

Manual/Auto |

| Power Supply |

AC 220V, 50/60Hz |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| Semiconductor Cutting and Molding Machine |

|

| Plastic Cutting and Molding Machine |

|

Applications:

Trim And Form Machine - TJIN 003

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Power Supply: AC 220V, 50/60Hz

Operation Mode: Manual/Auto

Control System: PLC Control System

Safety Features: Emergency Stop Button, Safety Light Curtain

Trimming Size: Max. 110mm X 110mm

The Trim And Form Machine is a high precision, efficient and reliable auto trim & form system designed for the electronic components industry. It is manufactured by TJIN, a well-known brand in the industry, and is the model number 003.

Application

The Trim And Form Machine is used in the production process of electronic components such as resistors, capacitors, diodes, and transistors. It is used to trim and form the leads of these components in order to achieve a specific shape and size, making them suitable for various electronic devices.

Scene

The Trim And Form Machine is commonly used in factories and manufacturing plants that produce electronic components. It is a crucial equipment in the production line, as it ensures the accuracy and consistency of the trimmed and formed leads, which directly affects the quality of the final product.

The machine is usually placed in a clean and organized environment, with proper ventilation to avoid any damage to the electronic components. It is operated by trained workers who are responsible for monitoring and controlling the machine's performance.

Features

The Trim And Form Machine is an advanced piece of equipment that offers a variety of features to enhance the trimming and forming process:

- Auto Trim & Form System: The machine has an automatic mode that can be activated to perform the trimming and forming process without manual intervention, increasing efficiency and accuracy.

- High Precision: With its PLC control system, the machine can achieve high precision in trimming and forming the leads of electronic components, ensuring their proper functioning in electronic devices.

- Efficient: The machine has a high production speed, making it suitable for large-scale production of electronic components.

- Reliable: The Trim And Form Machine is made with high-quality materials and advanced technology, ensuring its durability and reliability in the long run.

- Easy to Operate: The machine has a user-friendly interface and can be operated by workers with minimal training, making it easy to use in production settings.

Overall, the Trim And Form Machine - TJIN 003 is an essential piece of equipment in the electronic components industry, providing high precision, efficiency, and reliability in the trimming and forming process. It is a must-have for any factory or manufacturing plant that produces electronic components.

Customization:

TJIN Trim And Form Machine Customization Service

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Forming Size: Max. 110mm X 110mm

Safety Features: Emergency Stop Button, Safety Light Curtain

Control System: PLC Control System

Trimming Size: Max. 110mm X 110mm

Air Consumption: Approx. 100L/min

Key Features: Plastic Cutting and Molding Machine, Auto Frame Loader, High Speed Cutting and Separating System

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!