Auto Trim & Form System

PRODUCT ADVANTAGES:

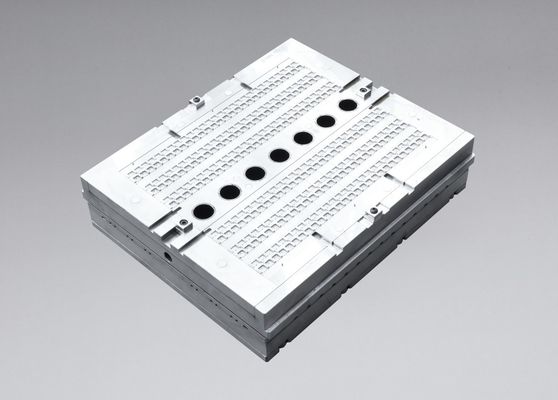

1. Using imported raw materials, utilizing imported advanced equipment for manufacturing and testing, the equipment has high precision and stable performance;

2. Customized according to the needs of strong wear resistance, high service life, quality assurance, after-sales worry-free.

Product Description:

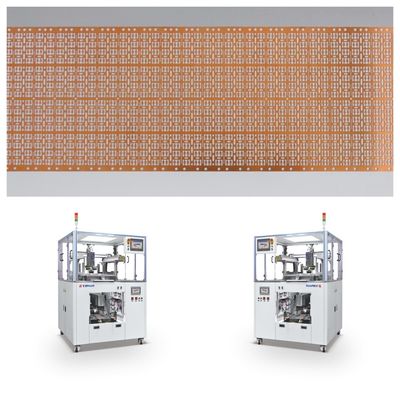

Trim And Form Machine

The Trim And Form Machine is a high precision, efficient and user-friendly Trim and Form System, designed for automatic punching and forming of electronic components. It is the perfect solution for manufacturers looking to streamline their production process and increase productivity.

Product Overview

The Trim And Form Machine is a state-of-the-art Trim/Form Machine that is perfect for trimming and forming electronic components. It has been designed with the latest technology to provide the highest level of accuracy and efficiency in the trimming and forming process.

Key Features

- Trimming Size: With a maximum trimming size of 110mm X 110mm, this machine can easily handle a wide range of electronic components, making it versatile for different production needs.

- Power Supply: The machine runs on an AC 220V, 50/60Hz power supply, making it compatible with most standard power outlets.

- Air Pressure: The machine requires an air pressure of 0.5MPa for optimal performance, ensuring consistent and precise trimming and forming of components.

- Dimensions: Measuring at approximately 1,200mm X 1,200mm X 1,500mm, the Trim And Form Machine has a compact design, making it easy to fit into any production space.

- Forming Speed: With an impressive speed of approximately 0.8 seconds per piece, this machine can handle large volumes of components in a short amount of time, increasing productivity and efficiency.

User-Friendly Design

The Trim And Form Machine has been designed with the user in mind, with a simple and intuitive interface that makes it easy to operate. The machine also has safety features in place to ensure the well-being of the user and prevent accidents.

Efficient and High Precision

The Trim And Form Machine is equipped with advanced technology that guarantees high precision in the trimming and forming process. This ensures that each component is trimmed and formed accurately, reducing the risk of errors and increasing overall efficiency.

Conclusion

The Trim And Form Machine is a reliable and efficient Automatic Punching and Forming System that delivers high precision results. Its user-friendly design and impressive speed make it a valuable asset for any electronic component manufacturer. With its compact size and versatile capabilities, it is a must-have for streamlining production processes and increasing productivity.

Main features:

Equipment function: after plastic sealing product cutting foot bending molding separation and so on;

Applicable packages: SOP/SSOP and other series;

Punching power: servo motor on the power-3~5T;

Cutting speed: 60-100 strokes / min (SPM: 60-100)

Separation speed: 40-60 strokes / min (SPM: 40-60)

Control system: PLC (Omron)

Operating system: touch screen + buttons, display UPH/SPM punch counting;

Receiving structure: material tube receiving (tube), automatic tube discharge compatible cartridge bulk receiving;

Safety protection system: the equipment has a leakage protection device, emergency stop button device and all the main protective doors are equipped with SENSOR protection device;

Technical Parameters:

| Semiconductor Tendon Cutting Machine |

Trim and Form System |

| Model |

TFM-1100 |

| Weight |

Approx. 500kg |

| Trimming Size |

Max. 110mm X 110mm |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| Air Consumption |

Approx. 100L/min |

| Forming Size |

Max. 110mm X 110mm |

| Control System |

PLC Control System |

| Air Pressure |

0.5MPa |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

Applications:

Trim And Form Machine for High Efficiency and Precision in Semiconductor Manufacturing

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Power Consumption: Approx. 1.5kW

Safety Features: Emergency Stop Button, Safety Light Curtain

Control System: PLC Control System

Air Consumption: Approx. 100L/min

Trimming Size: Max. 110mm X 110mm

The TJIN 003 Trim And Form Machine is a state-of-the-art semiconductor trim and form equipment designed for high efficiency and precision in integrated circuit manufacturing and electronic component production. It is a tendon cutting and molding machine that provides reliable and quality results, making it an essential tool for any semiconductor manufacturing process.

Application in Semiconductor Manufacturing

The TJIN 003 Trim And Form Machine is specifically designed for use in the semiconductor industry. It is used to cut and mold tendons in electronic components such as integrated circuits, making it an essential part of the semiconductor manufacturing process. With its high efficiency and precision, it helps improve the overall production process and ensures the quality of the final product.

Key Features and Benefits

- High Efficiency: The TJIN 003 Trim And Form Machine is built with high-speed motors and advanced cutting and molding technology, allowing it to complete tasks quickly and efficiently.

- Safety: This machine is equipped with an emergency stop button and a safety light curtain, ensuring the safety of the operator and preventing accidents.

- Precision: The PLC control system and advanced cutting and molding technology of this machine ensure precise and accurate results, meeting the strict standards of the semiconductor industry.

- Quality: With its precise cutting and molding capabilities, the TJIN 003 Trim And Form Machine helps maintain the quality of electronic components, contributing to the overall quality of the final product.

- Reliable: Made in China, the TJIN 003 Trim And Form Machine is built with high-quality materials and components, ensuring its reliability and durability for long-term use.

Product Usage and Scenario

The TJIN 003 Trim And Form Machine is used in various stages of the semiconductor manufacturing process. It is typically used after the assembly of electronic components, where it cuts and molds the tendons to the required size and shape. The machine is also used during quality control processes, ensuring that all electronic components meet the necessary standards.

The machine is operated by trained technicians and is typically used in a controlled and clean environment to prevent any damage or contamination of the electronic components. With its compact design and easy operation, the TJIN 003 Trim And Form Machine can be used in a variety of production scenarios, making it a versatile tool for any semiconductor manufacturing facility.

In conclusion, the TJIN 003 Trim And Form Machine is an essential tool for high efficiency and precision in semiconductor manufacturing. With its advanced features, safety measures, and reliable performance, it is a valuable asset for any integrated circuit manufacturing and electronic component production facility. Trust in TJIN for quality and reliable semiconductor cutting and molding machines.

Customization:

TJIN Trim And Form Machine - Model TFM-1100

Customized Services

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Model: TFM-1100

Trimming Speed: Approx. 0.5 Seconds Per Piece

Forming Size: Max. 110mm X 110mm

Safety Features: Emergency Stop Button, Safety Light Curtain

Trimming Size: Max. 110mm X 110mm

Key Words: Trim and Form System, Semiconductor Trim and Form Equipment, Plastic Cutting and Molding Machine

Our Trim And Form Machine, model TFM-1100, is a highly efficient and reliable solution for your trimming and forming needs. With a trimming speed of approximately 0.5 seconds per piece, it is capable of handling large volumes of work in a short amount of time.

The forming size of our machine is a maximum of 110mm X 110mm, making it suitable for a wide range of products. Additionally, we offer customized services to ensure that our machine meets your specific needs and requirements.

Our Trim And Form Machine is designed and manufactured in China under the brand name TJIN, ensuring high quality and durability. It is equipped with safety features such as an emergency stop button and a safety light curtain to ensure the safety of your operators.

With our Trim And Form Machine, you can expect precise trimming and forming of your products, thanks to its advanced technology and precision engineering. It is suitable for a variety of industries, including the semiconductor industry, as it is a semiconductor trim and form equipment. It is also ideal for plastic cutting and molding, making it a versatile solution for your manufacturing needs.

Packing and Shipping:

Packaging and Shipping

To ensure safe and secure delivery, our Trim And Form Machine is carefully packaged and shipped using high-quality materials and reliable shipping methods.

Each machine is first wrapped in protective materials, such as bubble wrap and foam, to prevent any damage during transit. It is then placed in a sturdy cardboard box and sealed with packaging tape.

For international orders, we use reputable shipping companies to ensure timely and efficient delivery. Our team also takes extra care to properly label each package with the necessary customs documentation to avoid any delays or issues.

Upon arrival, our customers can expect their Trim And Form Machine to be in pristine condition, ready to be put to use in their production line.

Should there be any concerns or issues with the packaging or shipping of your machine, please do not hesitate to contact our customer support team for assistance.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: What is the function of this product?

A: This product is a Trim And Form Machine that is used to trim and form electronic components.

- Q: What is the power source of this product?

A: This product is powered by electricity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!