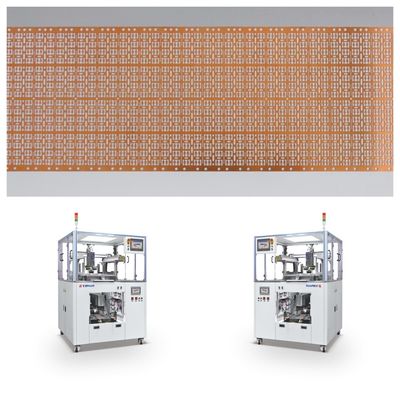

Intelligent Full Automatic Bar Cutting, Forming And Separating System

Main Features:

Function of the equipment: Cutting, bending and separating collection of products after plasticizing;

Punching speed: 50~100 punches/minute (SPM:50~100)

Applicable packages: SOP/SSOP/TSOP/MSOP/TSOP/TO/DIP series;

Punching power: servo motor upper power-3~5T.

Control system: PLC (Omron)

Operating system: touch screen + operating buttons, display UPH/SPM punching number counting function

Detection system: feeding and discharging double mirror CCD image detection

Feeding mechanism: rotary double magazines feeding

Charging mechanism: automatic conversion of cascading tube tray for charging (tube loading)

Safety protection system: the equipment is equipped with leakage protection device, emergency stop button device and all the main door guards are equipped with SENSOR protection device, after the door guards are opened, the system should make a certain response to protect personal safety.

Option 1: CCD visual inspection device;

Option 2: MES system networking function;

Product Description:

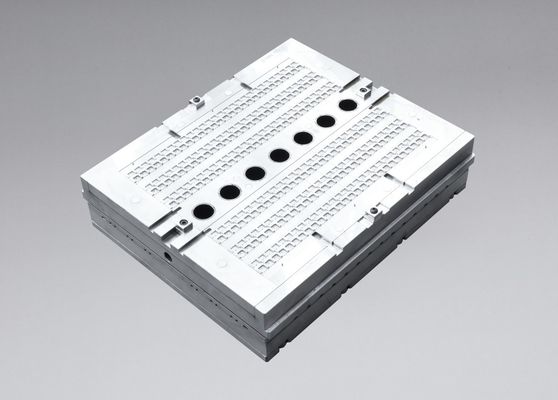

Product Overview - Trim And Form Machine

The Trim And Form Machine, also known as TFM-1100, is a highly efficient and reliable semiconductor trim and form equipment. With its automatic punching and forming system, it provides high precision and versatility in the cutting and molding process.

Weighing approximately 500kg, this machine is designed to handle heavy-duty work and can withstand continuous usage. Its robust and durable structure ensures long-term performance and minimal maintenance cost.

The Trim And Form Machine is equipped with a high-speed forming speed of approximately 0.8 seconds per piece, making it one of the fastest machines in its category. This enables quick production and reduces the processing time, resulting in increased productivity.

The TFM-1100 offers a maximum forming size of 110mm X 110mm, providing flexibility in the size of the final product. It can accommodate a wide range of semiconductor components, making it suitable for various industries.

Safety is a top priority when it comes to operating any machinery, especially in the semiconductor industry. The Trim And Form Machine comes with essential safety features such as an emergency stop button and a safety light curtain. These features ensure the protection of the operator and prevent any accidents from occurring.

With its advanced technology and precision engineering, the TFM-1100 guarantees high precision in the forming process. It can produce accurate and consistent cuts, resulting in a uniform and professional finish of the final product.

The Trim And Form Machine is suitable for a wide range of applications, including cutting and forming of various semiconductor components such as diodes, transistors, and resistors. Its versatility makes it an essential tool for any semiconductor manufacturing company.

Overall, the Trim And Form Machine - TFM-1100 is a must-have for any semiconductor manufacturing company. Its combination of high precision, efficiency, reliability, and safety features make it a top choice for cutting and molding processes. Invest in this machine and experience a significant increase in productivity and quality of your products.

Features:

- Product Name: Trim And Form Machine

- Control System: PLC Control System

- Air Pressure: 0.5MPa

- Weight: Approx. 500kg

- Trimming Speed: Approx. 0.5 Seconds Per Piece

- Power Supply: AC 220V, 50/60Hz

- Semiconductor Tendon Cutting Machine

- High Precision Trimming and Forming

- Efficient and Fast Processing

- Easy to Operate and Maintain

- Durable and Sturdy Construction

- Precision Trimming with Minimal Material Loss

- Flexible and Versatile Trimming Options

- PLC Control for Precise and Consistent Results

- Adjustable Trimming Speed for Different Needs

- Compact and Space-Saving Design

- Low Power Consumption

- Suitable for Various Types of Semiconductor Materials

Technical Parameters:

| Semiconductor Trim and Form Equipment |

|

| Control System |

PLC Control System |

| Forming Size |

Max. 110mm X 110mm |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Power Consumption |

Approx. 1.5kW |

| Trimming Speed |

Approx. 0.5 Seconds Per Piece |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

| Power Supply |

AC 220V, 50/60Hz |

| Air Consumption |

Approx. 100L/min |

| Trimming Size |

Max. 110mm X 110mm |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| High Speed Cutting and Separating System |

|

| Semiconductor Tendon Cutting Machine |

|

Applications:

TJIN Trim And Form Machine TFM-1100

Product Overview

The TJIN Trim And Form Machine TFM-1100 is a highly efficient and versatile machine used for plastic cutting and molding. It is specifically designed for the semiconductor industry, making it the perfect choice for precision cutting and molding of semiconductor tendons.

Product Features:

- Brand Name: TJIN

- Model Number: 003

- Place of Origin: China

- Model: TFM-1100

- Safety Features: Emergency Stop Button, Safety Light Curtain

- Air Consumption: Approx. 100L/min

- Power Supply: AC 220V, 50/60Hz

- Operation Mode: Manual/Auto

Applications:

The TJIN Trim And Form Machine TFM-1100 is widely used in the semiconductor industry for cutting and molding of plastic materials. It is suitable for a variety of applications such as:

- Semiconductor Tendon Cutting: The TFM-1100 is specifically designed for precision cutting of semiconductor tendons, ensuring accurate and efficient production.

- Auto Frame Loading: With its manual and automatic operation modes, the TFM-1100 can be easily integrated with an auto frame loader, making it suitable for mass production.

- Plastic Molding: The TFM-1100 can also be used for molding of plastic materials, making it a versatile machine for a wide range of applications.

Product Advantages:

The TJIN Trim And Form Machine TFM-1100 offers several advantages that make it the top choice for plastic cutting and molding:

- Efficiency: The TFM-1100 can handle high volumes of production with its automatic mode, ensuring maximum efficiency and productivity.

- Precision: With its safety light curtain and emergency stop button, the TFM-1100 ensures accurate and precise cutting and molding of plastic materials.

- Reliability: Made with high-quality materials and advanced technology, the TFM-1100 is a reliable and durable machine that guarantees long-term performance.

- Ease of Use: The TFM-1100 is designed with user-friendly controls and can be easily operated in both manual and automatic modes, making it suitable for all skill levels.

Conclusion:

The TJIN Trim And Form Machine TFM-1100 is a top-of-the-line machine that offers efficiency, precision, reliability, and ease of use. Its applications in the semiconductor industry make it an essential tool for production processes. With its advanced features and top-notch performance, the TFM-1100 is the perfect choice for all your plastic cutting and molding needs.

Customization:

Customization Service for TJIN Trim And Form Machine - Model TFM-1100

Product Attributes:

- Brand Name: TJIN

- Model Number: 003

- Place of Origin: China

- Operation Mode: Manual/Auto

- Air Consumption: Approx. 100L/min

- Power Supply: AC 220V, 50/60Hz

- Forming Speed: Approx. 0.8 Seconds Per Piece

Introducing our TJIN Trim And Form Machine - Model TFM-1100, a high-efficiency and precision plastic cutting and molding machine. With our Auto Trim & Form System, semiconductor tendon cutting has never been easier.

Customization Service:

At TJIN, we understand that every business has unique needs and requirements. That's why we offer customization services for our TFM-1100 model. Our team of experts will work closely with you to tailor the machine to meet your specific production needs and standards.

Benefits of Customization:

- Increased production efficiency

- Improved precision and accuracy

- Optimized operation mode (manual/auto)

- Reduced air consumption

- Adapted power supply (AC 220V, 50/60Hz)

- Enhanced forming speed (approx. 0.8 seconds per piece)

Don't settle for a one-size-fits-all solution. Choose TJIN and experience the benefits of a customized Trim And Form Machine that meets your unique production needs. Contact us today for more information.

Packing and Shipping:

Packaging and Shipping for Trim And Form Machine

Package Contents:

- 1 Trim And Form Machine

- 1 Power Cord

- 1 Instruction Manual

Packaging:

The Trim And Form Machine will be carefully packed in a sturdy cardboard box to ensure its safe arrival.

Shipping:

The Trim And Form Machine will be shipped via a reputable courier service to the specified address. Shipping costs will be calculated at the time of purchase and may vary depending on the destination.

Please allow 3-5 business days for processing and handling before the item is shipped out.

Once the item has been shipped, a tracking number will be provided to track the delivery status.

If there are any issues with the delivery, please contact our customer service team for assistance.

Thank you for choosing our Trim And Form Machine, we hope it brings you satisfaction and convenience in your work.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product made?

A: This product is made in China.

- Q: What is the function of this product?

A: This product is a Trim And Form Machine, used for trimming and forming electronic components.

- Q: What is the voltage requirement for this product?

A: This product has a voltage requirement of 220V.

If you are interested it , we can talk in detail.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!