Semiconductor Cutting and Molding Device

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: What is the function of this product?

A: This product is a Trim And Form Machine that is used to trim and form electronic components.

- Q: What is the power source of this product?

A: This product is powered by electricity.

Technical Parameters:

| Semiconductor Tendon Cutting Machine |

Trim and Form System |

| Model |

TFM-1100 |

| Weight |

Approx. 500kg |

| Trimming Size |

Max. 110mm X 110mm |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| Air Consumption |

Approx. 100L/min |

| Forming Size |

Max. 110mm X 110mm |

| Control System |

PLC Control System |

| Air Pressure |

0.5MPa |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

Product Main Features:

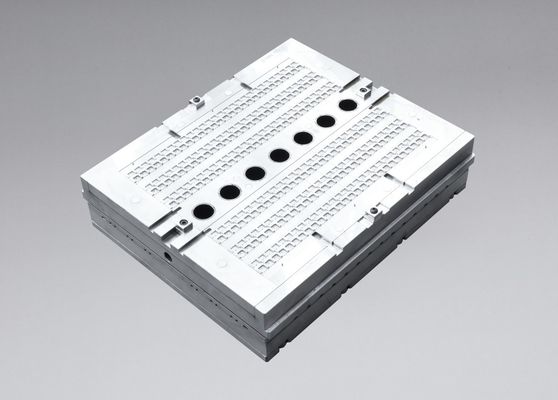

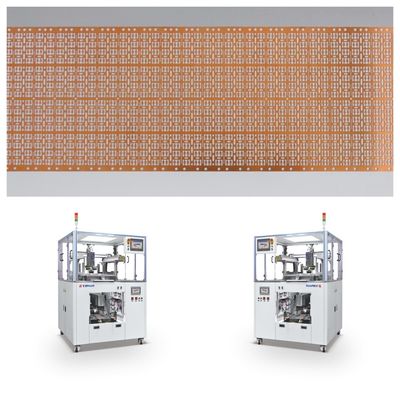

Function of the equipment: Cutting, bending and separating collection of products after plasticizing;

Punching speed: 50~100 punches/minute (SPM:50~100)

Applicable packages: SOP/SSOP/TSOP/MSOP/TSOP/TO/DIP series;

Punching power: servo motor upper power-3~5T.

Control system: PLC (Omron)

Operating system: touch screen + operating buttons, display UPH/SPM punching number counting function

Detection system: feeding and discharging double mirror CCD image detection

Feeding mechanism: rotary double magazines feeding

Charging mechanism: automatic conversion of cascading tube tray for charging (tube loading)

Safety protection system: the equipment is equipped with leakage protection device, emergency stop button device and all the main door guards are equipped with SENSOR protection device, after the door guards are opened, the system should make a certain response to protect personal safety.

Option 1: CCD visual inspection device;

Option 2: MES system networking function;

Customization:

TJIN Trim And Form Machine - Model TFM-1100

Customized Services

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Model: TFM-1100

Trimming Speed: Approx. 0.5 Seconds Per Piece

Forming Size: Max. 110mm X 110mm

Safety Features: Emergency Stop Button, Safety Light Curtain

Trimming Size: Max. 110mm X 110mm

Key Words: Trim and Form System, Semiconductor Trim and Form Equipment, Plastic Cutting and Molding Machine

Our Trim And Form Machine, model TFM-1100, is a highly efficient and reliable solution for your trimming and forming needs. With a trimming speed of approximately 0.5 seconds per piece, it is capable of handling large volumes of work in a short amount of time.

The forming size of our machine is a maximum of 110mm X 110mm, making it suitable for a wide range of products. Additionally, we offer customized services to ensure that our machine meets your specific needs and requirements.

Our Trim And Form Machine is designed and manufactured in China under the brand name TJIN, ensuring high quality and durability. It is equipped with safety features such as an emergency stop button and a safety light curtain to ensure the safety of your operators.

With our Trim And Form Machine, you can expect precise trimming and forming of your products, thanks to its advanced technology and precision engineering. It is suitable for a variety of industries, including the semiconductor industry, as it is a semiconductor trim and form equipment. It is also ideal for plastic cutting and molding, making it a versatile solution for your manufacturing needs.

Packing and Shipping:

Packaging and Shipping

To ensure safe and secure delivery, our Trim And Form Machine is carefully packaged and shipped using high-quality materials and reliable shipping methods.

Each machine is first wrapped in protective materials, such as bubble wrap and foam, to prevent any damage during transit. It is then placed in a sturdy cardboard box and sealed with packaging tape.

For international orders, we use reputable shipping companies to ensure timely and efficient delivery. Our team also takes extra care to properly label each package with the necessary customs documentation to avoid any delays or issues.

Upon arrival, our customers can expect their Trim And Form Machine to be in pristine condition, ready to be put to use in their production line.

Should there be any concerns or issues with the packaging or shipping of your machine, please do not hesitate to contact our customer support team for assistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!