Tendon cutting and molding machine

Customization:

Customization Service for TJIN Trim And Form Machine - Model TFM-1100

Product Attributes:

- Brand Name: TJIN

- Model Number: 003

- Place of Origin: China

- Operation Mode: Manual/Auto

- Air Consumption: Approx. 100L/min

- Power Supply: AC 220V, 50/60Hz

- Forming Speed: Approx. 0.8 Seconds Per Piece

Introducing our TJIN Trim And Form Machine - Model TFM-1100, a high-efficiency and precision plastic cutting and molding machine. With our Auto Trim & Form System, semiconductor tendon cutting has never been easier.

Customization Service:

At TJIN, we understand that every business has unique needs and requirements. That's why we offer customization services for our TFM-1100 model. Our team of experts will work closely with you to tailor the machine to meet your specific production needs and standards.

Benefits of Customization:

- Increased production efficiency

- Improved precision and accuracy

- Optimized operation mode (manual/auto)

- Reduced air consumption

- Adapted power supply (AC 220V, 50/60Hz)

- Enhanced forming speed (approx. 0.8 seconds per piece)

Don't settle for a one-size-fits-all solution. Choose TJIN and experience the benefits of a customized Trim And Form Machine that meets your unique production needs. Contact us today for more information.

Main features:

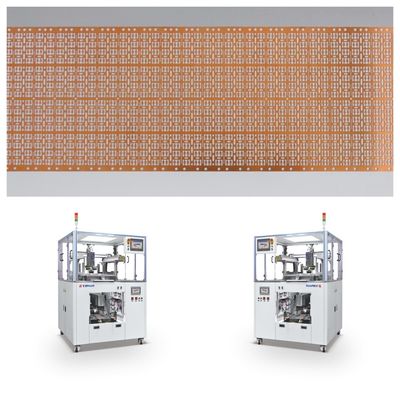

Equipment function: after plastic sealing product cutting foot bending molding separation and so on;

Applicable packages: SOP/SSOP and other series;

Punching power: servo motor on the power-3~5T;

Cutting speed: 60-100 strokes / min (SPM: 60-100)

Separation speed: 40-60 strokes / min (SPM: 40-60)

Control system: PLC (Omron)

Option 1: CCD visual inspection device;

Option 2: MES system networking function.

Applications:

TJIN Trim And Form Machine TFM-1100

Product Overview

The TJIN Trim And Form Machine TFM-1100 is a highly efficient and versatile machine used for plastic cutting and molding. It is specifically designed for the semiconductor industry, making it the perfect choice for precision cutting and molding of semiconductor tendons.

Product Features:

- Brand Name: TJIN

- Model Number: 003

- Place of Origin: China

- Model: TFM-1100

- Safety Features: Emergency Stop Button, Safety Light Curtain

- Air Consumption: Approx. 100L/min

- Power Supply: AC 220V, 50/60Hz

- Operation Mode: Manual/Auto

Applications:

The TJIN Trim And Form Machine TFM-1100 is widely used in the semiconductor industry for cutting and molding of plastic materials. It is suitable for a variety of applications such as:

- Semiconductor Tendon Cutting: The TFM-1100 is specifically designed for precision cutting of semiconductor tendons, ensuring accurate and efficient production.

- Auto Frame Loading: With its manual and automatic operation modes, the TFM-1100 can be easily integrated with an auto frame loader, making it suitable for mass production.

- Plastic Molding: The TFM-1100 can also be used for molding of plastic materials, making it a versatile machine for a wide range of applications.

Product Advantages:

The TJIN Trim And Form Machine TFM-1100 offers several advantages that make it the top choice for plastic cutting and molding:

- Efficiency: The TFM-1100 can handle high volumes of production with its automatic mode, ensuring maximum efficiency and productivity.

- Precision: With its safety light curtain and emergency stop button, the TFM-1100 ensures accurate and precise cutting and molding of plastic materials.

- Reliability: Made with high-quality materials and advanced technology, the TFM-1100 is a reliable and durable machine that guarantees long-term performance.

- Ease of Use: The TFM-1100 is designed with user-friendly controls and can be easily operated in both manual and automatic modes, making it suitable for all skill levels.

Conclusion:

The TJIN Trim And Form Machine TFM-1100 is a top-of-the-line machine that offers efficiency, precision, reliability, and ease of use. Its applications in the semiconductor industry make it an essential tool for production processes. With its advanced features and top-notch performance, the TFM-1100 is the perfect choice for all your plastic cutting and molding needs.

Technical Parameters:

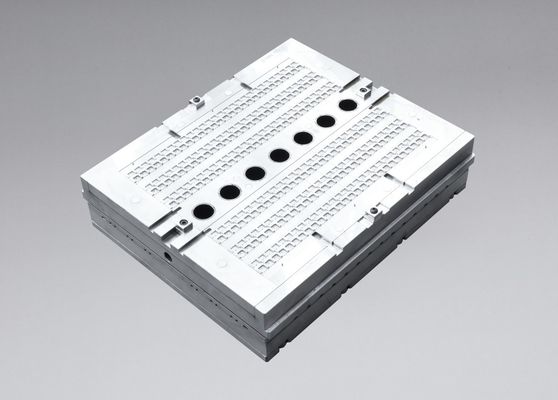

| Semiconductor Trim and Form Equipment |

|

| Control System |

PLC Control System |

| Forming Size |

Max. 110mm X 110mm |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Power Consumption |

Approx. 1.5kW |

| Trimming Speed |

Approx. 0.5 Seconds Per Piece |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

| Power Supply |

AC 220V, 50/60Hz |

| Air Consumption |

Approx. 100L/min |

| Trimming Size |

Max. 110mm X 110mm |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| High Speed Cutting and Separating System |

|

| Semiconductor Tendon Cutting Machine |

|

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product made?

A: This product is made in China.

- Q: What is the function of this product?

A: This product is a Trim And Form Machine, used for trimming and forming electronic components.

- Q: What is the voltage requirement for this product?

A: This product has a voltage requirement of 220V.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!