Auto Frame Loader

Product Features:

- Product Name: Trim And Form Machine

- Forming Speed: Approx. 0.8 Seconds Per Piece

- Safety Features: Emergency Stop Button, Safety Light Curtain

- Power Consumption: Approx. 1.5kW

- Dimensions: Approx. 1,200mm X 1,200mm X 1,500mm

- Model: TFM-1100

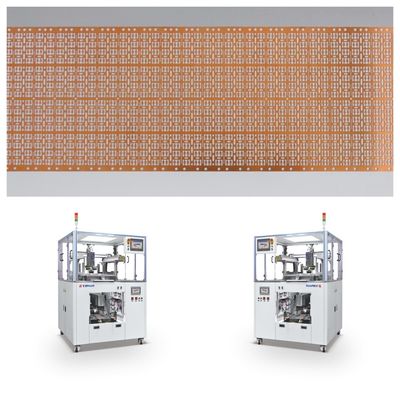

- Semiconductor Tendon Cutting Machine

- Auto Frame Loader

- Trim and Form System

Tube cutting and molding machine is also called automatic punching and cutting system. According to the different forms of product separation and tube loading, it can be freely combined with loading, punching, discharging and collecting, which is flexible and highly efficient.

Function: Mainly used for cutting, molding, separating and assembling tubes of semiconductor back-end packaging products.

Applicable packages: SOT / SOD / TSOT / SOP and other products;

Tendon cutting speed: 120-180 strokes/minute (SPM: 120-180)

Punching power: servo motor upper power-3~5T;

Control system: PLC (Omron)

Operating system: touch screen + buttons, display UPH/SPM punching and cutting count;

Feeding structure: rotary double magazines feeding;

Receiving structure: cartridge receiving (bulk)

Product Description:

Trim And Form Machine: A High Speed Solution for Precision Trimming of Semiconductor Components

Semiconductor components play a crucial role in various electronic devices, and their precision and quality are essential for the smooth functioning of these devices. To meet the increasing demand for perfectly trimmed and formed semiconductor components, we are proud to introduce our latest product - the Trim And Form Machine.

Safety Features

The Trim And Form Machine is equipped with advanced safety features to ensure the protection of operators and prevent accidents. An Emergency Stop Button is located at an easily accessible location, allowing operators to stop the machine immediately in case of an emergency. Additionally, a Safety Light Curtain is installed to detect any obstructions or interference, automatically stopping the machine to prevent accidents.

High Speed Trimming and Forming

The Trim And Form Machine is designed to provide a highly efficient and speedy solution for trimming and forming semiconductor components. With a trimming speed of approximately 0.5 seconds per piece and a forming speed of approximately 0.8 seconds per piece, this machine can significantly increase productivity and reduce production time.

Precision Trimming

Our Trim And Form Machine is equipped with a high-speed cutting and separating system, ensuring precision trimming of semiconductor components. This system allows for accurate and consistent cuts, resulting in perfectly trimmed components every time. This precision ensures the smooth functioning of electronic devices and reduces the risk of defects.

Compact and Lightweight Design

The Trim And Form Machine has a compact and lightweight design, making it easy to install and move around the production facility. With an approximate weight of 500kg and dimensions of 1,200mm x 1,200mm x 1,500mm, this machine can fit into small spaces without compromising on performance.

Conclusion

In today's fast-paced world, the demand for semiconductor components is constantly increasing, and the need for precision and efficiency in their production is crucial. The Trim And Form Machine is the perfect solution for this, offering safety, speed, precision, and compact design in one package. With this product, we aim to provide a reliable and efficient solution for semiconductor trimming and forming, contributing to the growth of the electronics industry.

Technical Parameters:

| Semiconductor Cutting and Molding Machine |

|

| Model |

TFM-1100 |

| Forming Speed |

Approx. 0.8 Seconds Per Piece |

| Safety Features |

Emergency Stop Button, Safety Light Curtain |

| Forming Size |

Max. 110mm X 110mm |

| Trimming Size |

Max. 110mm X 110mm |

| Air Pressure |

0.5MPa |

| Trimming Speed |

Approx. 0.5 Seconds Per Piece |

| Operation Mode |

Manual/Auto |

| Power Supply |

AC 220V, 50/60Hz |

| Dimensions |

Approx. 1,200mm X 1,200mm X 1,500mm |

| Semiconductor Cutting and Molding Machine |

|

| Plastic Cutting and Molding Machine |

|

Applications:

Trim And Form Machine - TJIN 003

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Power Supply: AC 220V, 50/60Hz

Operation Mode: Manual/Auto

Control System: PLC Control System

Safety Features: Emergency Stop Button, Safety Light Curtain

Trimming Size: Max. 110mm X 110mm

The Trim And Form Machine is a high precision, efficient and reliable auto trim & form system designed for the electronic components industry. It is manufactured by TJIN, a well-known brand in the industry, and is the model number 003.

Application

The Trim And Form Machine is used in the production process of electronic components such as resistors, capacitors, diodes, and transistors. It is used to trim and form the leads of these components in order to achieve a specific shape and size, making them suitable for various electronic devices.

Scene

The Trim And Form Machine is commonly used in factories and manufacturing plants that produce electronic components. It is a crucial equipment in the production line, as it ensures the accuracy and consistency of the trimmed and formed leads, which directly affects the quality of the final product.

The machine is usually placed in a clean and organized environment, with proper ventilation to avoid any damage to the electronic components. It is operated by trained workers who are responsible for monitoring and controlling the machine's performance.

Features

The Trim And Form Machine is an advanced piece of equipment that offers a variety of features to enhance the trimming and forming process:

- Auto Trim & Form System: The machine has an automatic mode that can be activated to perform the trimming and forming process without manual intervention, increasing efficiency and accuracy.

- High Precision: With its PLC control system, the machine can achieve high precision in trimming and forming the leads of electronic components, ensuring their proper functioning in electronic devices.

- Efficient: The machine has a high production speed, making it suitable for large-scale production of electronic components.

- Reliable: The Trim And Form Machine is made with high-quality materials and advanced technology, ensuring its durability and reliability in the long run.

- Easy to Operate: The machine has a user-friendly interface and can be operated by workers with minimal training, making it easy to use in production settings.

Overall, the Trim And Form Machine - TJIN 003 is an essential piece of equipment in the electronic components industry, providing high precision, efficiency, and reliability in the trimming and forming process. It is a must-have for any factory or manufacturing plant that produces electronic components.

Customization:

TJIN Trim And Form Machine Customization Service

Brand Name: TJIN

Model Number: 003

Place of Origin: China

Forming Size: Max. 110mm X 110mm

Safety Features: Emergency Stop Button, Safety Light Curtain

Control System: PLC Control System

Trimming Size: Max. 110mm X 110mm

Air Consumption: Approx. 100L/min

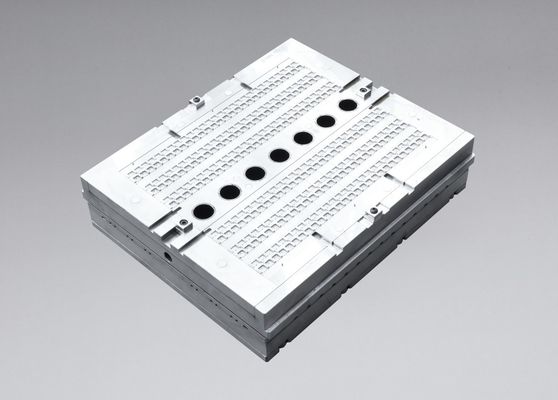

Key Features: Plastic Cutting and Molding Machine, Auto Frame Loader, High Speed Cutting and Separating System

Packing and Shipping:

Trim And Form Machine Packaging and Shipping

Packaging:

The Trim And Form Machine will be packaged in a sturdy cardboard box to ensure its safe delivery. The machine will be securely wrapped in bubble wrap and placed in the box, along with all necessary accessories such as user manual and power cord.

Shipping:

The Trim And Form Machine will be shipped via a reputable courier service, such as FedEx or UPS. The shipping cost will be calculated based on the weight and destination of the package. Customers will have the option to track their package using a tracking number provided by the courier.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is TJIN.

- Q: What is the model number of this product?

A: The model number of this product is 003.

- Q: Where is this product made?

A: This product is made in China.

- Q: What is the function of this machine?

A: This machine is used for trimming and forming metal components.

- Q: What is the power source of this machine?

A: The power source of this machine is electricity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!